(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 30~1500kg/h

- Voltage: 220V/380V

- Dimension (L*W*H): 4000*1300*4200mm

- Weight: 1000~2000kg

- Power ( W): 27KW

- Country: lagos

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without

Peanut proteins: Extraction, modifications, and applications

- Type: peanut oil processing machine

- Production capacity: 3.5-4 KG/H

- Voltage: 220 V 50 Hz

- Main components: Motor, Pressure vessel

- Weight: 13KG

- Dimension (L*W*H): 460*160 *350MM

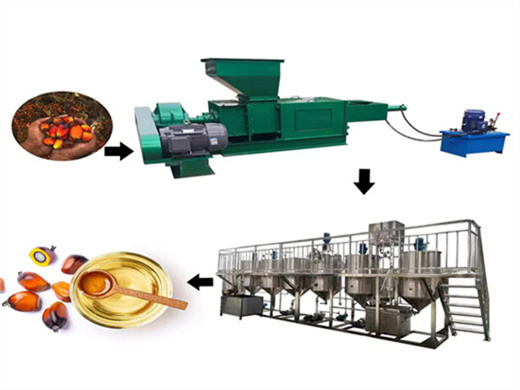

Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent (n-hexane) extraction [29]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

The underlying reasons for the efficient extraction of peanut

- Usage: peanut oil

- Production capacity: 1-500T/D

- Voltage: 380V

- Weight: about 40 tons

- Dimension (L*W*H): according to oil plant specifications

- Power (W ): less than 85 kW

In recent years, many studies have been made to improve the aqueous extraction efficiency of peanut oil through pretreatment. The free oil recovery was enhanced from 48.50% to 65.00% through storage pretreatment of peanut paste (Li et al., 2021), suggesting that paste storage has a positive effect on oil aggregation to a certain extent.

The leaching procedure mainly makes use of the solid-liquid extraction principle to select certain fat-dissolving organic solvents to extract the peanut oil. Generally speaking, the leaching solvent should meet the following conditions: good fat solubility, stable physiochemical properties, easy separation from the fat and meal, and be safe

Advanced nut processing with the peanut oil press machine

- Type: cooking oil extraction machine

- Production capacity: 250-300 KG/H

- Voltage: 380V

- Weight: 2200 kg

- Dimension (L*W*H): 2000x1200x2500mm

- Power (W ): 3KW

In the ever-evolving world of nut processing, the Peanut Oil Press Machine emerges as a prime example of advancement and efficiency. This state-of-the-art machine leverages electrical type technology to streamline and enhance the extraction of superior quality peanut oil, thus positively impacting the consumption of peanut oil.

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

Aqueous enzymatic extraction of peanut oil body and protein

- Raw Material: peanut

- Production capacity: 1500 kg/hour

- Warranty: 5 years

- Voltage: 220 V

- Main components warranty: 5 years

- Main components: pressure vessel, pump, others, gears, gearbox

Aqueous enzymatic extraction (AEE) is a new technology for extracting vegetable oil body which has the advantages of low energy consumption, product safety, mild reaction conditions, and simultaneous separation of oil and protein. Among the enzymes tested in the present work, Viscozyme L (compound plant hydrolase) exhibited the highest extraction activity during peanut oil extraction

Peanuts are the main oil crops and contain high nutrition, but the quality, color, taste and even the oil yield of the peanut oil extracted by different peanut oil extraction machine are different. These are inseparable from the causes of the press, but they are also related to the different processing methods.