What is the process flow of peanut oil refined?

- Type: peanut oil refinery machine

- Usage/Application: peanut, groundnut

- Voltage: 220 V/380 V/440 V

- Power (W): 18.5 KW/T

- Certification: ISO9001

- Weight: 30 tons

- Dimension (L*W*H): 48m *12M*15M(30TPD)

- Country: lagos

1. The 1000kg/d oil refinery machine heating power is 27kw, voltage is 380V, and it can refine all kinds of crude oil by screw oil press extracted. 2. It is made of food grade stainless steel and polished.

Peanut/Groundnuts Oil Processing | Hot & Cold Press

- Type: peanut oil refinery machine

- Production capacity: 98-100%

- Voltage: 380 V

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox, other

- Weight: 440 KG

- Dimension (L*W*H): 1400*1000*1500 mm

Peanut Oil Processing. Peanut oil is an edible oil extracted from peanuts (also known as groundnuts or ground beans). Peanut oil is usually extracted by two methods: pressing and extraction (Read more: solvent extraction of groundnut oil >>). Among them, the main process steps include cleaning, shelling, drying, pressing, and refining.

Step 4: Pressing. The peanuts are transfer by conveyor and fed through the hopper of screw press machine. Continuous transport of material by the screw shaft causes pressure to increase to a level needed, which increases friction inside the screw press and generates heat which lowers viscosity of the oil in the crushed seeds thereby increasing the oil flow rate.

Peanut Oil Production Line, Automatic Production Line for

- Usage: peanut oil

- Voltage: 380V-440V

- Power(W): 1.5-3kw

- Color: According to customer requirements

- Weight: different

- Dimension(L*W*H): according to capacity

The raw material which is used to produce fragrant peanut oil is fresh, full-grained, undamaged, mildew-free, free of insects and has not undergone an aging period. Raw materials would be cleaned by removing immature, damaged, and moldy grains during the cleaning process. 1.2 Process Flow of Peanut Oil Production Line

What are the main features of the screw peanut oil pressing machine? The screw peanut oil pressing machine is a device specifically designed for extracting oil from peanuts. Its working principle mainly relies on the rotation of the screw shaft to apply pressure, squeezing the oil out of the peanuts. 2024-10-30

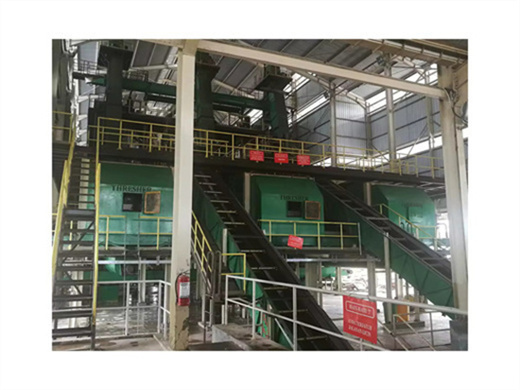

Batch type peanut oil refinery plant and continuous peanut

- Type: cooking oil refining machine

- Automatic grade: Semi-automatic

- Voltage: 220V /380V/440V

- Production capacity: 98%-100%

- Power (W): 15KW

- Dimension (L*W*H): 6000*700*5600mm

Second stage of batch type peanut oil refinery process is to Remove Free Fatty Acids(F.F.A.) with caustic Soda. This peanut oil refining process also called Neutralizing Process. The next peanut oil refining process is bleaching process. During peanut oil bleaching process, we usually use bleaching earth and activated carbon to remove colour.

Peanut Oil Refining Process: Degumming: The crude peanut oil is mixed with water and heated to remove phospholipids and gums. Neutralization: An alkaline solution (sodium hydroxide) is added to neutralize free fatty acids, forming soapstock, which is then separated. Decolorization: Removes pigments and other coloring agents using bleaching clay.

Offer Edible Oil Refinery Lines for Various Crude Oils Refining

- Raw Material: peanut

- Voltage: 380v/50Hz

- Dimension (L*W*H):1360*950*1170mm

- Power (W): up to specification

- Weight: up to specification

- Certification:ISO9001

The specific oil refining process for edible oil are detailed below. Edible Oil Refining Process Flow Chart. Degumming Stage; In the edible oil refining process, removing colloidal impurities from crude oil can be completed by physical, chemical or physicochemical methods, which is called degumming. hydration degumming is a very important step.

With Perennial years export experiences, our Small Edible Oil Refinery Equipment LYX2&3 has been welcomed in international markets. Welcome contact us. +86 15537739893