Complete 200 TPD Cotton Seed Oil Processing Plant installed

- Type: cottonseed oil plant

- Usage/Application: cottonseed

- Production capacity: 60-400 kg/h

- Voltage: Customizable

- Warranty: 1 year, 12 months

- Weight: 1100 KG

- Dimension (L*W*H): 1800*1200*1550 mm

- Country: indonesia

Recently, our client in indonesia ordered a 200 TPD high-capacity oil processing line to process cotton seeds. The main equipment involved in the cotton oil Processing plant are Seed Cleaner, cooker, Screw press, Neutralizer, bucket elevator and screw conveyor.

Cottonseed Oil Production Line - Oil mill

- Type: cottonseed oil processing machine

- Production capacity: 10-500tpd

- Voltage: 380V/50HZ

- Water (soften water): 150Kg/ T of oil

- Product Electrical consumption: 28Kwh/T oil

- Power (W): 7.5kw

Cottonseed de-hulling machines break the tough outer shell to access the oil-rich kernel and separate the cottonseed kernel from the hard shell to improve oil yield. Optional pneumatic transport systems separate hulls and kernels efficiently, ensuring better oil recovery.

If you are planning to set up a cottonseed oil refining plant or oil refinery equipment for other oilseeds, you are in the right place! We take the opportunity to intoduce Our Machinery, an ISO 9001 Company, a leading oil mill engineering firm, established in 1997, specialist in vegetable oil extraction and refinery field.

Cottonseed Oil Mill Plant

- Usage: cottonseed oil

- Production capacity: 93%-94%

- Voltage: 380V/customize

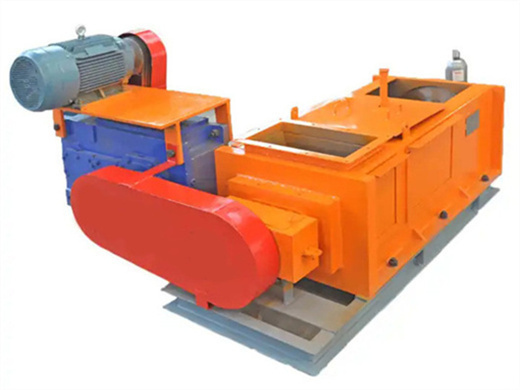

- Main components: motor, gearbox

- Weight: 830 KG

- Dimension (L*W*H): 2000*680*1460mm

The cottonseed oil production line offered by GOYUM is robust, versatile, reliable and efficient. This cottonseed oil production plant is based on practically proven technology which is not only energy efficient & environment friendly, but also economical.

They have similar structures as sunflower seeds. There is a hard outer null with an oil-bearing kernel inside it. The oil is extracted from the seeds or kernel of varieties of species of cotton plants. Cottonseed Oil offers a unique business opportunity. By 2028, the global cottonseed market will reach a value of over 5 billion dollars.

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cooking oil extraction machine

- Production capacity: 1700-2500kg/day (cold pressing)

- Weight: 450 KG

- Dimension (L*W*H): 1640*640*1200mm

- Warranty: 1 year

- Key selling points: Energy saving

Cracking: Adopting the toothed cracking roller to make the cotton seeds kernel into a right uniform pcs which can keep a moderate block size for squeezing out the oil. Flaking: To make cracked Cotton seeds kernel pcs into uniform smaller flakes with thickness ≤ 0.5mm, less powder, non-oil spilled, pinching softly by hand and the ratio of

The purpose of cottonseed pretreatment is to clean up impurities in cottonseed, adjust the moisture, temperature and internal structure of cottonseed, so that cottonseed can reach a good state before pressing, improving the production efficiency of cottonseed oil. The pre-treatment machine used in cotton seed oil processing plant includes

Goyum Screw Press - Oil Processing Machine Manufacturer

- Raw Material: cottonseed oil

- Production capacity: 1-100T/D

- Power (W) : 20-50KW

- Voltage: 380V/440v

- Dimension(L*W*H): depends on capacity

- Weight: depends on capacity

We are a Family Owned Company and Pioneer in Planning, Engineering, Manufacturing and Installation & Commissioning for Automatic Oil Mill Plant, Palm Kernel Oil Extraction Plant, Solvent Extraction Plant, Edible Oil Refinery Plant, Fish, Poultry & Animal Feed Plant, Oleochemical Plant Flour Mill Plant, Rice Mill Machinery, EFB, MSW, Plastic

Complete Equipment for Solvent Extraction Plant for Vegetable… The plant is designed to extract oil directly from oil seed containing less than 20% oil like soybean after flaking, or it extracts oils from pre-pressed, or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts…