Oil Press Plant Hcrank Oil Press in mozambique

- Type: sunflower oil press

- Usage/Application: sunflower

- Production capacity: 1TPD-1000TPD

- Voltage: 220V/380V/440V

- Weight : 30 tons

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Power (W): 18.5 KW/T

- Country: mozambique

Sunflower seeds is a common oilseeds, in which there are 45-54% oil content. Sunflower oil, with golden color, clear and transparent, fragrance oil, is a kind of popular edible oil among people. How to make sunflower oil using sunflower oil production machine? There is the main process of sunflower oil production line.

KK200 | Seed Oil Presses - Seed2Oil

- Type: sunflower oil processing machine

- Production capacity: 100% oil press machine

- Voltage: 220V/380V/440V

- Weight: 950KG

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Power (W): 5.5 ~ 18.5 KW

up to 400lbs – 200kg of seed per hour; Same design as KK100 but larger throughput with more powerful motor and larger screw and press chamber; Different screw profiles available for different seeds; Good for medium oil content seeds such as canola, sunflower, hemp, chia, soybean, flax and similar

Note: YZS-30, YZS-60, YZS-70 multi-function oil presses are specially designed for manufacturing sesame oil, but they also suitable to extract oil from groundnut, sunflower seeds and rape seeds. Complete Oil Pressing Process. Sunflower seeds are of two types. One the non-oil seed which is usually eaten as confectionery just after being roasted

Best Automatic Seed Oil Press Machine for Sunflower Oil

- Usage: sunflower oil

- Voltage: 380v

- Dimension (L*W*H): 900*750*1400 mm

- Oil keyword: Hydraulic oil extraction press

- Components main: Others

- Weight: 880 KG

YZS-30 seed oil press machine, equipped with latest design, is a new type of integrated automatic oil press machine that is widely used to process sesame seed, sunflower seeds, peanuts, walnuts and so on. Its raw material feeding capacity is about 0.2 to 0.4 kg when it turn on.

The electric cold oil press FX15 can process up to 15 kg/h of soft raw oil seeds, such as canola seeds or sunflower seeds. This is suitable for professional use in a oil mill, farmers shop or organic market with the aim of producing high quality cold pressed vegetable oils and it has been designed for continuous operation.

Efficient Sunflower Oil Production Machines

- Type: cooking oil extraction machine

- Production capacity: 100% oil refining equipment

- Power (W): 10-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): Depends on its capacity

- Weight: Depends on its capacity

3. Oil Expeller/Press: - Mechanically presses the sunflower seeds to extract the oil. - Can be either a cold press (preserves nutrients but has a lower yield) or hot press (higher yield but may lose some nutritional value). 4. Oil Filtration Machine: - Filters the oil to remove solid particles, impurities, and seed residue. - Produces clear

Mini oil mill ghani is most easy to use at homes/office/hospitals and oil is 100% pure, natural and efficacious for health. Features: Home Oil Press Machine used for Pressing of Peanuts, Coconut, Sesame, Soybean, Walnuts, Sunflowers seeds, Vegetable seeds, Flax seeds, Almond, Castor Seeds, Mustard seeds and so on..

Offers the Best Oil Press, Screw Oil Press

- Raw Material: sunflower

- Production capacity: 100% Indonesia cooking oil mill

- Power (W): 40kw/h

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 1000m*800m*30m

- Weight: 2000--5000 tons

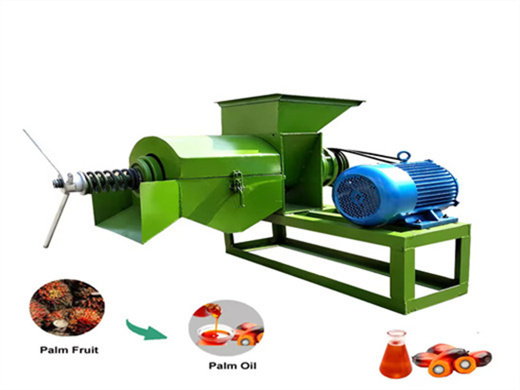

Screw Oil Press Introduction. Screw oil press is a compact-structured oil extrusion machine used for extracting edible oil from more than twenty kinds of oilseeds such as peanut, soybean, flaxseed, sunflower seed, rapeseed, etc. Different from integrated screw oil press machine, it is more suitable to large-scale cooking oil plants which produce various grades cooking oil.

The production process of sunflower oil is as follows: sunflower seeds screening - cleaning impurities - hulling - crushing - steaming - pressing - solvent extraction - filtration - refining - sunflower oil. First, we need to screen and clean sunflower seeds to remove impurities. Secondly, shell and crush the sunflower seeds with a sheller and crusher. Third, the crushed sunflower seeds will be steamed and fried to reduce the impact caused by moisture. Fourth, the steamed and fried sunflower seeds are pressed to form gross oil in a sunflower oil press. Fifth, the sunflower oil is extracted with solvents and filtered. Finally, the filtered sunflower oil is refined to form edible oil.