Hongde Provides Turnkey Oil Mill Plant, Oil Pressing Machine

- Type: peanut oil machine

- Usage/Application: peanut, groundnut

- Production capacity: 30-600 kg/h

- Voltage: 110/220v

- Advantage: High oil yield

- Weight: 220 KG

- Dimension (L*W*H): 1200*780*1100mm- 2200*1400*1700mm

- Country: zambia

The grains milling production line includes a grain cleaning machine, a net conveyor auger, a granary Run, an elevator, a double peeling machine , four set 30 novel milling machine and so on, one-stop production from raw materials to finished products, which can produce various specifications high mesh powder.

Peanut Oil Production Line - Zhengzhou Siwei Grain & Oil

- Type: peanut oil processing machine

- Voltage: 380 V

- Power (W): 5.5 kW-18.5 kW

- Certification: CE,BV,ISO9001

- Weight: Based on the capacity of the cooking oil press

- Dimension (L*W*H): 1910*550* 765 mm

2. The complete production line can achieve fully automated control. 3. High-performance, high-quality equipment coupled with Overseas door-to-door installation service ensures long-term stable operation of the equipment. 4. We undertake: peanut oil production line ranging:5 - 200TPD; peanut pretreatment, pre-pressing and solvent extraction

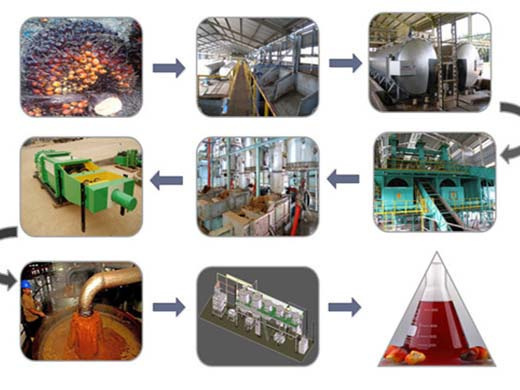

Peanut Oil Production Line. Henan Hongde Oil Machinery is a professional Peanut/Groundnut Oil Production Machine Manufacturer in China. Our company is dedicated to the design, installation, commissioning and technical training of peanut oil processing plant for 36+ years; we can provide a complete set of groundnut oil production machine turnkey projects with a processing capacity ranging from

Fully Automatic Groundnut/Peanut Oil Production Line

- Usage: peanut oil

- Voltage: 380 V

- Power (W): Standard

- Certification: CE,ISO

- Weight: standard

- Dimension (L*W*H): standard

Peanut Oil Production Line. Peanut is a kind of oilseed with high oil content. The oil can be obtained from peanuts by pressing process. Groundnut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid). Besides, there are also palmitic acid, stearic acid, and other saturated fatty acids which

Frequently asked questions about our factory and oil processing equipment. Why choose Hongde? Hongde machinery has developed projects including large scale oilseed pretreatment and pressing, oil extraction, oil refining and oil fractionation production line project,conveyor equipment project,corn/maize flour, grits, germ milling machines and corn processing lines,biodiesel technology

Peanut Oil Production Line - Edible Oil Expeller Machinery

- Type: cooking oil extraction machine

- Customized: Customized

- Color: as per requirement

- Delivery time: Within 2 days

- Capacity: 180-250 Kg/H

- Package: Wooden Box

Peanut Oil Production Process and Operating Points. In order to ensure the nutrition, flavor, and safety of fragrant peanut oil and reduce the cost, we adopt a physical squeezed method in the peanut oil production line. And the features of the pressing line are: (1) Extraction adopts pure physical pressing method to completely avoids the

Henan Hongde Oil Machinery is a professional Peanut/Groundnut Oil Production Machine Manufacturer in China. Our company is dedicated to the design, installation, commissioning and technical training of peanut oil processing plant for 36+ years; we can provide a complete set of groundnut oil production machine turnkey projects with a processing

Efficient Peanut Oil Production Line For Groundnut Oil Press

- Raw Material: peanut

- Production capacity: 350-7000kg/h cooking processing machine

- Power (W): according to the capacity of the cooking processing machine

- Voltage: 380V or local voltage

- Dimension (L*W*H): 900*850*1550mm

- Weight : 1000KG

The peanut shelling machine is the first step in the peanut oil production line and is used to quickly remove the peanut shells and ensure the integrity of the peanut kernel. With high shelling efficiency and low crushing rate, it provides high-quality raw materials for subsequent processes.

Stir the oil slowly to cool it to a certain temperature, and then pump the cooled oil into the oil filter for coarse filteration. Cooling and fine filtration process: pump the coarse filtered oil into cooling oil tank to further cool it to a lower temperature, and colloid impurities in crude oil temperatures condense gradually in the critical