Effect Of Different Sterilization Methods On The Extracted

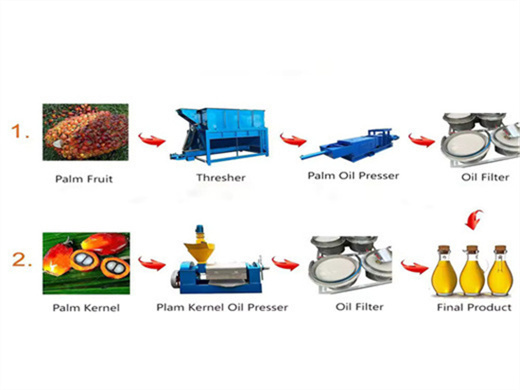

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1-2000TPD

- Voltage: 220V/380V/440V

- Weight: 30 tons

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Power (W): 18.5 KW/T

- Country: lusaka

Sterilization is one of the key processes in any palm oil mill plant. Fresh fruit bunches (FFB) are cooked using steam as the heating medium. The sterilization process uses a lot of steam, consuming about thirty (30%) to sixty (60%) percent of the total process steam, depending on the type of sterilizer technology used.

Minimizing water consumption in oil palm sterilization using

- Type: palm oil processing machine

- Production capacity: 45%

- Voltage: 380 V

- Key Selling Points: Multifunctional

- Weight: 1100 KG

- Dimension (length x width x height): 1700*1400*1850

In a palm oil mill, Fresh Fruit Bunches (FFB) have to be delivered within 24 h after being harvested to avoid increased FFA, which would degrade palm oil quality (Osawa et al., 2007). Fig. 1 shows the typical palm oil milling process. The bunches are sterilized immediately in a sterilizer using steam generated by a boiler.

Sterilizer steam source pressure and steam consumptions in terms of kg per tonne FFB, and its power consumption in a palm oil mill, using different sterilizer technologies can be summarised as follows: Horizontal sterilizer (New), 1.5 bar : 110 – 130 Vertical Sterilizer, 4 bar : 305 – 355 & 200 kW power

Dynamic Sterilization with Avatar Technology by HSS

- Usage: palm oil

- Production capacity: 500-1000kg/24H

- Voltage: 220/380v, 380v

- Main components: motor, pump, motor

- Weight: 240KG

- Dimension (L*W*H): 1850*1050* 1750mm

With over 40 years of experience in the oilseed extraction industry, Mr. Hon Swee Sang is a highly accomplished professional who began his career with a Diploma in Mechanical Engineering. He started as a Maintenance Supervisor in a sugar mill in Papua New ethiopia and later went on to work as a Mill Engineer at Tawau Edible Oil and Kudat Edible Oil Mill, Sabah. During this time, he gained

The high palm oil price has fueled the in-vestment in more efficient palm oil process-ing technology to reduce labour dependence through automation. The biggest challenges facing oil palm mills are the efficiency of oil and kernel extraction, product quality and environmental issues. The patented Tilting Sterilizer® is the

Vertical Sterilizer Design of Building Palm Oil Processing

- Type: cooking oil extraction machine

- Production capacity: 5TPD-100TPD

- Dimension (length x width x height): 67*35*50 cm

- Voltage: 220 VAC 50 Hz

- Weight: 12 kg

- Main components: motor, motor

PDF | On Oct 18, 2019, I Rizkya and others published Vertical Sterilizer Design of Building Palm Oil Processing Plant to Cost Efficiency | Find, read and cite all the research you need on ResearchGate

available sterilizer technology systems are briefly evaluated and compared. Control systems are used in various waste treatment technology systems, such as POME (palm oil mill effluent) polishing plant and biogas digester plant, to monitor and optimize the biological treatment processes. The latest

An innovative hybrid steam-microwave sterilization of palm

- Raw Material: palm

- Voltage: 220 V/380 V

- Weight: 500

- Dimension (length*width*height): 700*800*780 mm

- Main components: motor, pump

- Oil Product Keyword: Seed Oil Pressing Machine

In palm oil milling station, sterilization protects oil quality from free fatty acid (FFA) by inactivating lipase activities on the fresh fruit bunch (Omar et al., 2018). High content of FFA is one of the most significant issues encountered in majority palm oil mill stations (Japir et al., 2017; Jusoh, Rashid, & Omar, 2013).

Based on 75 selected palm oil mills data from 2009-2013, Continuous Sterilizer (CS) system and Conventional Sterilizer (CV) system recorded 2.7% and 1.3% respectively under the Excellent category.