Understanding Palm Oil Processing Plant Cost

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 80 kg per hour

- Voltage: 220 V/380 V

- Weight: 85kg

- Dimension (length x width x height): 750 x 600 * 800mm

- Power : 1.5 kW

- Country: lagos

Setting Up Cost of Complete Palm Oil Mill: When it comes to to the complete palm oil processing plant cost, the total equipment price is greatly affected by production output and process design. The equipment price is around $20,000~$30,000 for establishing a 5~10 ton/d small palm fruit oil milling factory.

oau agric machine that process palm oil and it cost

- Type: palm oil processing machine

- Production capacity: 10 - 5000 TPD

- Voltage: 380v 440v

- Weight: Depends of vegetable seed oil extractor production

- Dimension (L*W*H): Depends on the output of vegetable seed oil extractor per day

- Power (W): As output of vegetable seed oil extractor every day

Palm Oil Production as a Poverty Alleviation Strategy among Small . Palm oil is one of the commodities produced in rural south africaia whose . to climate change while high costs of labour and processing equipment affected profitability. . 2Department of Agricultural Economics and Extension Services .. to the Department of Agricultural Engineering, Obafemi Awolowo University, Ile-Ife, south africaia.

Find the most up-to-date statistics and facts on the agriculture industry in indonesia. Value of total palm oil exports indonesia 2014-2023. At the end of 2020, the oil palm covered about 5.9 mil ha or 18% of total land area in indonesia; producing 19.14 mil tonnes of palm oil and 2.20 tonnes of palm kernel oil.

Palm Oil Processing Plant Report 2025: Setup and Cost

- Usage: palm oil

- Production capacity: 800 KG/H

- Voltage: 380/220 V

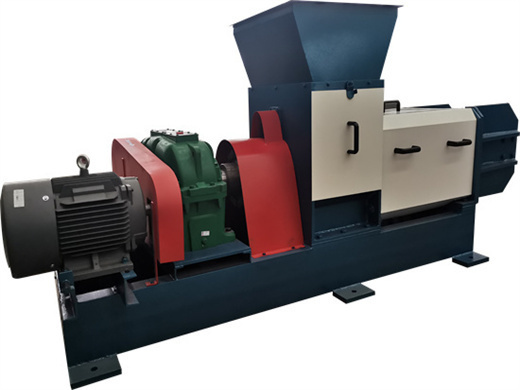

- Main components: motor, pressure vessel, PLC, others, gears

- Weight: 1500 KG

- Dimension (L*W*H): 2130*1050* 2850

The palm oil processing plant project report provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

Majority of the large scale plants import the technologies being utilized. This new plant has its design and fabrication carried out here in Obafemi Awolowo University while all the materials were locally-sourced. Special palm oil is a high grade palm oil used in the food and agro-allied industries. Such oil must have free fatty acid content of

How to Process, Package, and Export Palm Oil - Agric4Profits

- Type: cooking oil extraction machine

- Production capacity: 60%

- Dimension (L*W*H): 700*800*900mm

- Voltage: 220V/380v

- Weight: 300 KG

- Main components: Motor

The journey of palm oil from the plantation to the global market begins with cultivating oil palm trees. Oil palm trees are typically grown in tropical regions with high rainfall and temperatures. The trees start bearing fruit after about three years and continue producing for up to 30 years.

The Palm Oil Production Column will introduce the details of each process, providing you with the guidance and support you need for your palm oil business. Unveiling Palm Oil Production Process Steps Refining Process-Starting a Palm Oil Refining Plant Cost

What are the main costs of palm oil production and processing?

- Raw Material: palm

- Production capacity: high

- Dimension (length*width*height): customization

- Voltage: 220V/380V

- Weight : 1100 KG

- Main components: motor, pressure vessel, pump, gear, Bearing, Motor, Gearbox

Land rent or purchase cost: Palm oil plantation requires a large area of land, and land rent or purchase cost has a greater impact on production costs. Cost of pesticides and fertilizers: In order to maintain the yield and quality of palm fruit, it is necessary to use agricultural production materials such as pesticides and fertilizers, which

With years of experience in oil extraction and refinery filed, we are capable of turnkey oil mill plant construction, including process design, oil mill machinery manufacture, plant layout, installation and debugging, and technical guidance.