Cottonseed Oil Mill / Oil Extraction Plant Manufacturers

- Type: cottonseed oil extraction plant

- Usage/Application: cottonseed

- Residual oil in flour: less than 1%

- Solvent consumption : less than 2 kg/t

- Crude oil moisture and volatile matter: ≤ 0.30%

- Moisture of finished food: ≤ 13% (adjustable)

- Energy consumption: no more than 15 KWh /T

- Country: rwanda

The major cottonseed producing countries in the world are India, China, USA, Brazil, Uzbekistan, Turkey, European Union, Mexico, lusaka, Ethiopia, south africaia, Sudan, indonesia, lusaka, rwanda. We can deal with any question on the installation of oil extraction plants and allied machinery. Our plants have been exported around the world.

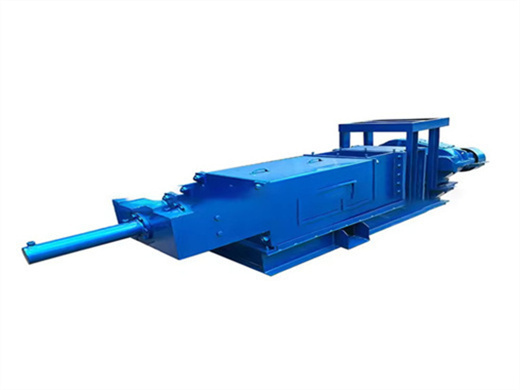

Solvent Extraction Plant Technology and Equipments

- Type: cottonseed oil processing machine

- Production capacity: 100%

- Voltage: 220V/380V

- Weight: 1200 kg

- Dimension (L*W*H): 450* 230*350 mm

- Power (W ): 7.5 kW

Cotton Seed Solvent Extraction Plant: Cotton seed oil is a cooking oil which extracted from the seeds of cotton plant of various species. An undelinted seed composition is about:8-10% of lint, 18-22% of oil, 30-35% of meal and 30-35% of hulls.

Cotton Seed Processing Plants; Vegetable Oil Refining; Main Risks of Oil Processing; Palm Oil; Archives. May 2013; April 2013; January 2013; December 2012; October 2012; August 2012; July 2012; June 2012; May 2012; March 2012; Categories. Best Solvent for Solvent Extraction; Buying Oil Mill Plant; Crude Palm Oil Processing; Jatropha Seed Oil

soybean cotton oil extraction machine in rwanda

- Usage: cottonseed oil

- Automatic Grade: Semi-automatic

- Production capacity: 1TPD-1000TPD

- Dimension (L*W*H): 1.5*2.6*3.6M

- Power (W): 7.5kw

- Voltage: 220V/380V

If you want to build a top quality Cottonseed Oil Mill Plant with or without refning plant, the very first step is to buy high quality oil extraction and refinery machinery - Lesser power consumption, minimum noise during operation and continuous production for better productivity. The following is the HOT Sale Unite for small scale cottonseed oil mill:

In this section we use Magnetic Separator, Vibrating Sieve, de-stoner, decorticator (Cotton seeds used hammering decorticator). Through cleaning the impurity, you can reduce the lost of oil & improve the oil yield and the environment of production plant. The material has been produced after pretreatment contains the impurities ≤ 0.1%.

Factory Price Groundnut Oil Extraction Machine in rwanda

- Type: cooking oil extraction machine

- Voltage: 380V/220V or as required

- Dimension (L*W*H): 2700*820*1400mm

- Main components: Motor

- Main components warranty: more than 5 years

- Weight: 1800 KG

The mini groundnut oil production plant unit is suitable for vegetable oil extraction from many different oil-bearing materials as soybeans, peanuts, cotton seeds, sunflower seeds, sesame seeds, palm kernel, coconut etc. Cost of Groundnut O il Production Machine : $5000~$15000 (Reference Price)

Import Major Focus on importing dairy feeds, animal feeds, agro-commodities (Soyabean, Cashew etc), edible oils, specialty oils from West African Countries like lesotho, lusaka, rwanda, malawi, Sierra Leone to name a few. Recognized expertise in importing cottonseed oil cake, established as one of the top importers in India

rwanda oil extraction plant - Complete Oil Processing

- Raw Material: cottonseed oil

- Production capacity: 10-20 kg/hour

- Dimension (L*W*H): 850*650 *1100

- Voltage: 220/380 V

- Weight: 600 KG

- Main components: Pressure container

We offer cotton seed oil processing plant for either small scale or big scale according to differnet needs of our customer. The small scale cotton seed oil processing plant involves several processes like entry into the shaker room, where the cotton seeds are cleaned, the cleaned cotton is send through the grin sand where linter’s are removed from the cotton seed. The next step is passing them through hullers, where the tough seed coats are removed.

Cottonseed oil extraction production line solves crude oil extraction from cottonseed cake through processing flows of solvent extracting, mixture oil filtration, wet bran treatment of dephenolizaiton and mechanical desolvent, and low temperature drying, evaporation, gas stripper to obtain crude cottonseed oil.