Sunflower Oil Refining Process Essentials for Optimal Effects

- Type: sunflower oil refinery equipment

- Usage/Application: sunflower

- Voltage: 380 V/50 HZ

- Power (W): 15 KW

- Certification: ISO

- Weight: 1200kg

- Dimension (L*W*H) : 1700*1100*1600mm

- Country: nairobi

Sunflower Oil Refining Equipment List; Sunflower oil hydration and degumming equipment: 1. Hydration tank (intermittent, same as alkali refining pot) 2. Vacuum dryer 3. Desolventizer (dedicated to remove residual solvents from leaching branched hairy sunflower oil) Sunflower alkaline refining and deacidification machines: 1. Alkali refining pot 2.

Sunflower Oil Production Line

- Type: sunflower oil refinery machine

- Production capacity: 20- 2000 TPD

- Voltage: 380v 440v

- Weight: Depends on China oil machinery for seed production

- Dimension (L*W) *H): Depends on China oil machinery for seed production per day

- Power (W): Depends on China oil machinery for seed production

The oil is extracted directly from the sunflower seeds by a screw type oil press machine. Sunflower seeds are cold-pressed (or hot pressed) at a certain temperatures, and the protein-rich cake that remains after the seeds are processed into oil is used as animal feed, retaining 99% of the nutrients in sunflower oil without the use of chemical solvents.

Compared with batch sunflower oil refining equipment, semi-continuous sunflower oil refining equipment has moderate investment and lower oil loss, so it is widely selected. Semi-continuous equipment is added to the deacidification and deodorization tower and fatty acid tank to achieve continuous deacidification and deodorization processes.

Edible Oil Refinery Technology

- Usage: sunflower oil

- Production capacity: 98-100%

- Voltage: 380 V

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox, other

- Weight: 1200 KG

- Dimension (L*W*H): 2300*1600*1600 mm

There are great and stable demand for high quality edible oils around the world. In order to enjoy more competive edges in cooking oil industry, it is necessary to equip your oil mill plant with professional oil refining equipment, or you can just start your own business by setting up an edible oil refinery plant. Edible Oil Refining Types

Flow Chart - Sunflower Oil Refining Process. Pretreatment: The pretreatment stage involves sedimentation and filtration of the raw sunflower seed crude oil to remove large particles and impurities. Degumming Stage: Soluble impurities in crude sunflower oil not only affect stability of the oil but also the efficiency of oil refining and further

Optimization of the Physical Refining of Sunflower Oil

- Type: cooking oil refining machine

- Production capacity: 3-5 kg/hour

- Dimension (length x width x height): 380 * 152 * 320mm

- Voltage: 220 V/110 V

- Weight: 6.6KG

- Key Selling Points: Easy to operate

and oil flow rate, (Foil) were related to the processing conditions, while the others (number of stages, N, liquid height, Hliquid, and equipment diameter, D) were related to the equipment design. The retention time (trt) of the oil in the deodorizer was defined as a function of the five factors selected, as shown in Equation 1. [] [ ] ( )[ ] [ ]

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

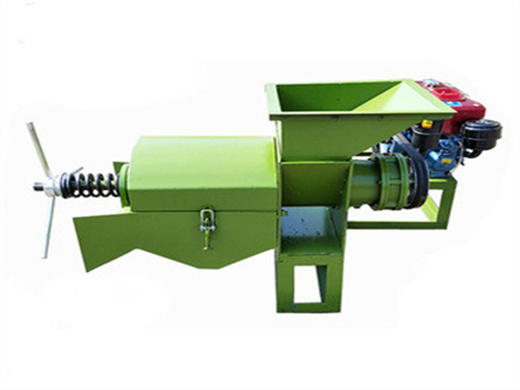

Sunflower Oil Refinery Plant

- Raw Material: sunflower

- Production capacity: 80-5000 kg/h

- Dimension (length x width x height): 450*165* 285 mm

- Voltage: 110 V/220 V

- Weight: 11 KG

- Main components: Engine oil

The demand for oils with a lower degree of unsaturation than those of traditional oils has significantly increased the availability of oils of high thermostability. Refining the crude sunflower oil on our Tinytech refinery machine will eventually produce an additive free product having good oxidative, flavor and cold-test stabilities. Idea

3. Sunflower oil refining process. First, hydrated degumming, mainly is to remove phosphatide inside crude sunflower oil in order to reduce oil loss and improve quality of oil . Second, alkali refining, using alkali to neutralize free fatty acid with by-product of soapstock, which is used for making soap.