How To Establish Small Scale Oil Mill of Cotton Seed? Mini

- Type: cottonseed oil press

- Usage/Application: cottonseed

- Voltage: 230-380-430

- Power (W): 40 kw/h

- Certification: CE and ISO9001

- Weight: 30 tons

- Dimension (L*W* H): 20m*16m*15m

- Country: ghana

Read more about cottonseed oil solvent extraction method >>. Set Up A Cottonseed Oil Mill Plant. This small small oil mill is not only suitable for cotton seeds, it is also ideal choice for extracting oil from many other oil seeds and nuts, such as mustard seed, peanut, flaxseed, linseed, poppyseed, groundnuts, sesame seed, canola seed, sunflower seed, soybeans, etc.

Overcoming the Processing Challenges of Cottonseed Oil

- Type: cottonseed oil processing machine

- Production capacity: 5-100T/DAY

- Voltage: 220v

- Main components: Motor

- Weight: 8100 kg

- Dimension (L*W*H): 760*1050*1450mm

The seed’s oil had become the primary source of vegetable oil in the country by 1890, and by 1900, the U.S. was crushing more than 2 million tons of cottonseed. The oil’s cooking potential was driven by popular products like Crisco, which was short for “crystallized cottonseed oil,” and Wesson cooking oil.

You must meet the conditions to squeeze. Steaming is used to increase the plasticity in cotton seeds and reduce the viscosity in refined oil.small olive press. 3. Pressing cotton seed. To ensure that cotton seed are squeezed, fried in the oil press, the oil’s moisture content is 1.5-2.5% and the temperature is about 125-130 degrees.

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Usage: cottonseed oil

- Voltage: According to customer demand

- Power(W): 1.5KW

- Color: Silver

- Weight: 850kg

- Dimension(L*W*H): 1050*950*1650

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

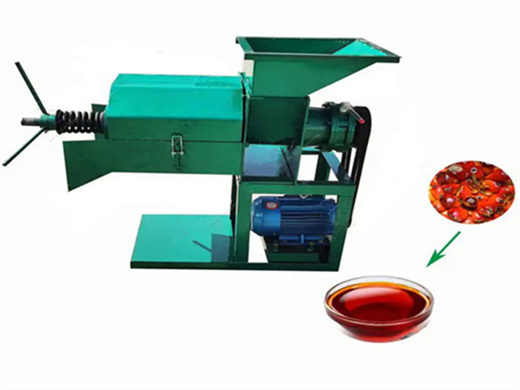

One of the widely used machine used in cottonseed oil manufacturing plant is screw cottonseed oil machine, a type of cottonseed oil machinery. It’s very simple in nature and can be used to extract oil from various seed plants. The screw cottonseed oil press is a mini cottonseed oil machine that can be used for small-scale extraction oil plants.

Cottonseed Oil Press Oil Extraction Oil Refinery Plant

- Type: cooking oil extraction machine

- Production capacity: 1TPD-1000TPD

- Voltage: 220V/380V

- Weight: 30 tons

- Dimension (L*W*H): 1.5*2.6*3.6M

- Power (W): 15KW

2. cottonseed oil pre-press→ cottonseed oil extraction→cottonseed oil refinery. Normally for input capacity more than 20 tons per day, it's better to adopt the second Cottonseed Oil Processing Plant processing method with better cost performance. Here we will introduce you the second method. Cottonseed Oil Processing Plant from Pre-Pressing

The cottonseed pretreatment equipment adjusts the internal structure of cottonseed to a state suitable for solvent extraction. The crude cotton seed oil and cottonseed cake can be obtained after being processed by the cottonseed oil pre-press. The cottonseed cake is transported to the leaching workshop to further produce cottonseed oil.

Cottonseed Oil Mill Plant

- Raw Material: cottonseed oil

- Production capacity: 5t/day-5t/hour

- Dimension (L*W*H): na

- Voltage: na

- Weight: KG

- Main components: Gearbox

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

The pretreatment equipment adjusts the temperature, moisture and internal tissue structure of the cottonseed to make the cottonseed reach a good state before pressing, which is convenient for extracting more oil during the pressing process. Cottonseed oil extraction process adopts the method of physical pressing, and the pressing efficiency of