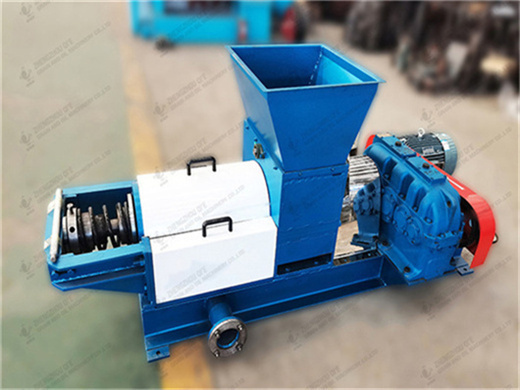

Palm Oil Pressing Processing Machinery Equipment

- Type: palm oil press

- Usage/Application: palm fruit, palm kernel

- Production capacity: 50-1000 kg/h

- Voltage: 220/380

- Main components: motor, pressure vessel, pump, PLC, others, gear, bearing, motor, gearbox

- Weight: 280 KG

- Dimension (L*W) *H): 1400*860*1260

- Country: afghanistan

In pressing stage, mechanical screw palm oil pressing machine is used to extract the oil out of digested palm pulp which is a mixture of oil, water, fibre and nuts. Hydraulic presses and the older centrifuges have been deemed almost redundant today as palm oil processing plants these days use specifically designed screw-presses much like the

Palm Oil Processing Machines

- Type: palm oil processing machine

- Voltage: Local voltage

- Power (W): Depends

- Certification: CE ISO

- Weight: 30 tons

- Dimension (L*W*H): 2000x1400x1850mm

3.Palm oil mil process of threshing: strong vibrations through the fruit from fruit bunches separated. Threshing station. 4.Mashing. Mixing tank will mash and crush palm fruit until broken after fruit threshing. 5.Palm oil mil process of pressing: There is also the steam heater in masher. The purpose of mashing is to separate the pulp and nut

Palm fruit pressing. The palm fruit pressing equipment independently developed by Hongde has the characteristics of high efficiency, high oil yield and good energy efficiency, and has been widely used in palm oil processing. Leave a Message

High Efficient Small Palm Oil Extractor Machine

- Usage: palm oil

- Production capacity: 100-130 kg/h

- Voltage: 380v,220v

- Main components: engine, gearbox

- Weight: 560 kg

- Dimension (L*W*H): 1300 *960*1420 mm

It is suitable for pressing and obtain crude ioil from heated and crushed palm fruit billets. It has the advantage of low core crushing ratem high extraction performancem no special moisture contents requirements on raw material, excellent manufacturing process, compact structure, large output, stable operation, easy maintenance and long

With more than 200 patented technologies as the core, Hongde Oil Machinery has overcome the high oil loss and high energy consumption problems in palm oil processing – from fresh fruit (FFB) sterilization and pressing to crude palm oil (CPO) refining and fractionation, the oil output rate of our palm oil equipment leads the industry by 5%-10%

Palm Oil Pressing Machines - Palm Oil Mill Machines

- Type: cooking oil extraction machine

- Production capacity: 5TPD

- Dimension (L*W*H): 270*50*350mm<br /Weight: 3KG

- Voltage: 0

- Main components: Bearing

- Oil type: Cooking oil

Palm fruits through elevator and conveyors, enters into upper steaming boiler of oil press machine. Stirring and heating with steam to destroy the emulsified state forming from oil and water, wherein the coagulation protein denaturation and to reduce the viscosity of the oil for further convenience of palm oil pressing process. Digesting

Sterilization as the first step in palm fruit pressing is critical to the quality of the final production-- palm oil. The purpose of sterilization process is, inactivate the activity of lipase and prevent the rise of free fatty acids; make the palm fruit easier to fall off from the fruit bunch; and soften the peel and make the oil easier to separate out.

Palm Oil Machine - Palm Oil Production Line

- Raw Material: palm

- purpose: cooking

- Material: Stainless steel

- Description: Semi-continuous

- color : fresh and bright

- smell : no unpleasant smell

Palm Oil Machine. Henan Hongde Cereals and Oils Machinery Co., Ltd. has been focusing on the research and development and manufacturing of palm oil processing machine for more than 37 years, providing a full set of solutions from palm fruit pressing to palm oil refining.

Low environment pollution palm oil milling production line. This palm fruit oil machine adopts process of sterilization, threshing, digesting, pressing, clarification, purification, drying, depericarper, crushing and final pressing. This mature design fulfills the lowest fuel consumption, steam driving, and self-sufficient energy supplying.