Cottonseed Oil Mill Plant

- Type: cottonseed oil refinery plant

- Usage/Application: cottonseed

- Supply Type: OEM/ODM

- Appearance: Pale or deep brown clarified liquid

- Refractive index: 1.500-1.510

- Density: 0.970-0.990

- Taste: Peculiar taste, bitter and spicy taste

- Country: johannesburg

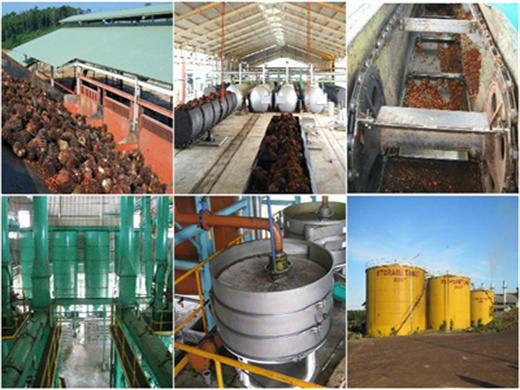

Cottonseed Oil Pressing / Expelling (by using Mechanical Screw type Oil Press); Cottonseeds can be pre-pressed before they get sent directly to the refinery plant. To handle 20 tons of cottonseed per day, the solvent extraction method is used with cottonseed oil prepress to take parts of the oil.

Cotton Seeds Oil Refinery Plants

- Type: cottonseed oil refinery machine

- Certification: Ce, ISO

- Layer: 10 - 44

- Filter medium: 0.8 Um

- Filter size: 100 - 400 mm

- Filter area: 0.078 - 7 M2

Oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining equipment. With the high degree of automation, the oil refining machinery can refine 20 kinds of oil, such as soybean, rape seeds, peanut, etc. in a small production line or in large

3.Cottonseed oil Refinery : A.Flow chart: Degumming →Deacidification →Decoloration → Deodorization →edible oil B. Points for cottonseed oil refining plant ♦ Cottonseed oil refinery can be divided into batch refining (50 t/d) depending on capacity.

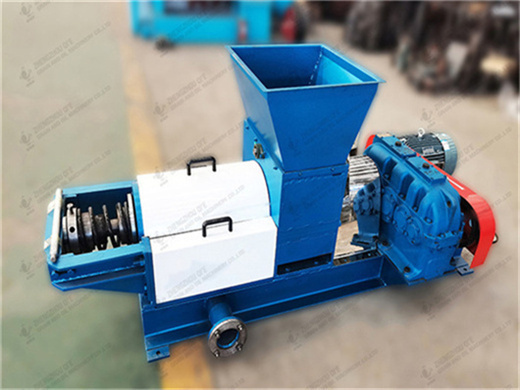

Cottonseed Oil Extraction Plant

- Usage: cottonseed oil

- Production capacity: 10T/24h

- Voltage: 380V

- Main components: Motor, gear, Bearing, Motor, Gearbox

- Weight: According to the capacity of the machine

- Dimension (L*W*H): According to the capacity of the machine

Cottonseed kernels contain 0.5%-2.5% of gossypol. After processed by the cottonseed oil refinery plant, the gossypol content in the oil is less than 0.01%. The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1.

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

Cottonseed Oil Production Line - Zhengzhou Siwei Grain & Oil

- Type: cooking oil refining machine

- Production capacity: 95%

- Power (W): 80000

- Voltage: 380 V

- Dimension (L*W*H): 8M*6M*5M

- Weight: 10T

The color is darker red than other oils. Only refined cottonseed oil can be consumed by humans. Siwei Group can provide full range of cottonseed oil solutions according to your needs, including site planning, engineering design, equipment manufacturing, installation and commissioning, as well as oil plant expansion and upgrades, etc. What can

Undecorticated Cottonseed obtained after Delinting process can be used as a raw material for Cottonseed Oil Extraction Plant. Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed. The working principle of the cotton

Complete Cottonseed Oil Production Lines. Cottonseed Oil

- Raw Material: cottonseed oil

- Voltage: 220 V, 380 V or other

- Dimension (L*W*H): depends on the capacity

- Power (W): 2.2 KW

- Weight: depends on capacity

- Color: depends on requirements

Cottonseeds can be once-pressed and then sent to the cottonseed oil refinery plant in small cottonseed oil plants. For cottonseed oil production lines with a capacity of over 20 TPD, a solvent extraction method is adopted to work together with cottonseed oil pre-press to extract the rest cottonseed oil.

Wintone as a professional edible oil refinery plant manufacture can provide design, manufacture, installation, calibration and after service of cottonseed oil refining equipment and other cooking oil processing plants.