Oils Fats Refining Equipment and Turnkey Plants

- Type: peanut oil refinery machine

- Usage/Application: peanut, groundnut

- Production capacity: 1-500T/D

- Voltage:380V

- Weight: changes with capacity

- Dimension (L*W*H): various with capacity

- Power (W): according to capacity

- Country: nigeria

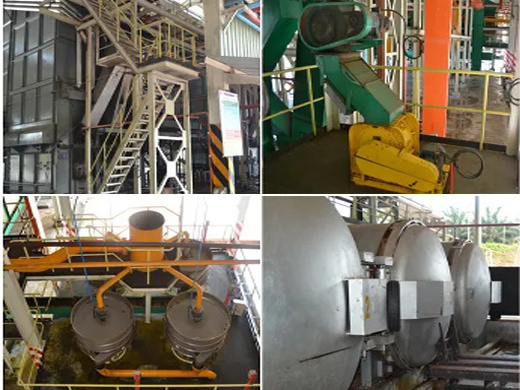

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Batch Type Small Edible Oil Refining Plant - Oil mill

- Type: peanut oil refinery machine

- After-sales Service: Online Service

- Guarantee: 1 Year, 2 Years

- Voltage: 380V, 380V

- Press Series: Second

- Structure: Horizontal

The Batch-type edible oil refining equipment is designed to handle various types of crude oils, including palm oil, soybean oil, sunflower oil, peanut oil, and more. It performs several refining processes in a batch mode, allowing for flexibility and control over the refining process.

In fact, as a responsible supplier of edible oil refining machine, we are explicit that the EXACT cost of the edible oil refinery machine is decided by various aspects, including capacity, oil property, requirement for final produced oil, local market, etc. The Edible Oil Refining Plant Cost in small scale level ranges $21,000~$115,000.

High quality edible oil refinery machine manufacturer

- Usage: peanut oil

- Production capacity: 1-50T/D

- Voltage: 380V /440V or local voltage

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): According to capacity

Discover high-efficiency edible oil refinery machines designed for optimal oil purification and processing. Suitable for various oils like soybean, sunflower, palm, and peanut, these machines ensure premium quality oil with advanced refining technology. Enhance your production with our durable and cost-effective solutions.

Cotton Seed Oil Refinery Plant. Oil Refining is the progress of removing impurities such as phospholipids, FFA, pigment, and off-flavor in cruel oil before edible application. An oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining

Edible Oil Refinery Machines for coconut,sunflower,peanut oil

- Type: cooking oil refining machine

- Production capacity: 100TPD

- Dimension (L*W*H): 2500*1200*1900mm

- Voltage: 220V/380V

- Weight: 550 KG

- Warranty: 1 year, 18 months

Small-scale edible oil refinery machines are designed to refine crude oils extracted from seeds, nuts, and other sources into pure, high-quality edible oils. These machines utilize advanced refining processes such as degumming, neutralization, bleaching, and deodorization to remove impurities and improve the color, flavor, and shelf life of the

Advantages of Lingfine Peanut oil refinery machine Advanced designed edible oil refining process. Lingfine designs advanced and professional edible oil refinery process to obtain high purity refined oil. It contains hydrated degumming, alkali refining deacidification, negative pressure decoloring process through blenching earth, deodorizing to

Tailored Edible Oil Refinery Machines and Process Solutions

- Raw Material: peanut

- Customized: Customized

- Final product: Grain oil

- Capacity: 5t 10t, 20t, 30t

- Features: Low consumption, high extraction rate

- Flour fineness: 60-100mesh

Customized Edible Oil refinery Plant Solutions Provider: Our Machinery. By exploring in-depth the nuances of different edible oil refinery processes and equipment, you can obtain high-quality refined oils, successfully start a profitable edible oil refining business, and make informed investment decisions.

Chemical Refining & Physical Refining Edible/vegetable oil refining is a step by step process. Refining oil removes phospholipids, pigments, off-flavors, free fatty acids and other impurities. The entire oil refining plant process comprises degumming/neutralization, bleaching, deoderization, and winterization.