Soybean Oil Making Machine Soya Oil Refinery in lesotho

- Type: soybean oil refinery machine

- Usage/Application: soybean

- Production capacity: 9000-10000 kg/h

- Voltage: 380V

- Weight: According to equipment capacity

- Dimension (L*W*H): 1200*400*900mm3

- Power (W): 18.5kw

- Country: lesotho

It is complete oil processing line that is composed of raw material pre-treatment section, oil pressing section, oil refining section and oil. Water content: 5 – 10 %; temperature: 105 – 110 degrees; Requiring Time: 60mins. Oil Pressing process: After preprocessing, the soybean and peanut are ready for oil expelling.

Efficient Soybean Oil Refinery Process and Machines for

- Type: soybean oil refinery machine

- Production capacity: 100%

- Voltage: 380V

- Weight: various

- Dimension (L*W*H): 1200*400*900mm3

- Power (W): 11KW

Soybean oil batch oil refinery machines is suitable for 1-30 tons/day small soybean oil refinery plant. The Pros of Mini Soybean Oil Refinery Plan: Compact Brilliance The equipment composition of mini/small soybean oil refining line is shown in the below figure, which mainly includes two refining tanks, decolorization tank, deodorization tank

Mini/Small Scale Edible Oil Refining Plant Projects by Our Machinery. Every year, we will export and set up many edible oil refinery machine in different contries, including India, Ghana, Zambia, Australia, Jamaica, south africaia, Tanzania, Zimbabwe, Namibia, lesotho, the United States, etc.

crude soybean oil refine machine in lesotho

- Usage: soybean oil

- Production capacity: 50T~100T/D

- Voltage: 220V/380V

- Weight: 1050 KG

- Dimension (L*W*H): 430*230*350

- Power ( W): According to capacity

Embark on a journey to premium soybean oil production with Hongde oil machinery! If you're seeking the pinnacle of soybean oil quality, we're your dedicated partner. Our all-encompassing soybean oil processing plant is at your service, complete with top-tier pretreatment gear, state-of-the-art extraction machines, and advanced refinery technology. We're here to craft a tailor-made turnkey project from the ground up, just for you.

Soybean oil is one of the most important edible oils in the world, and its processing process plays a crucial role in improving oil quality and yield. Soybean oil processing process is not only a technology, but also an art, which needs to go through several steps and links to ensure that the final product meets food safety and nutritional standards. Which process is the best to choose for processing soybean oil needs to be decided according to the market orientation of the oil plant, the size of the plant and other circumstances.

10TPD Peanut | Soybean Oil Press Plant& Refinery lesotho

- Type: cooking oil refining machine

- Voltage: 380v 50hz

- Weight: 140 KG

- Dimension (L*W*H): 920*480*760mm

- Components Main: motor, pressure vessel, pump

- Oil type: cooking oil, hemp oil

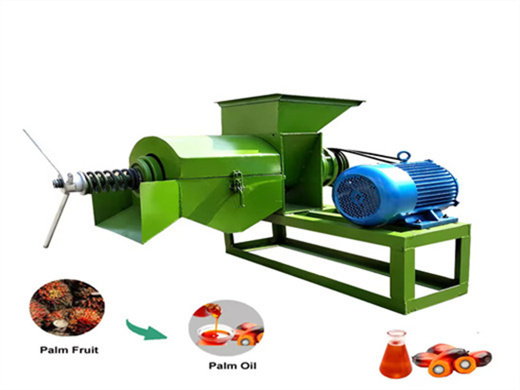

This 10TPD Peanut and Soybean Oil Press Plant and 3TPD Oil Refinery is in lesotho. Customer raw materials are soybean and peanuts, daily consumption of 10 tons of raw materials to produce 3 tons of oil, refined Nissan 3 tons.

The soybean oil discharged from soybean oil press machine contains many useless and unhealthy substances and impurities. In order to produce high quality edible oil, the first step is to filter all the organic impurities. (Related equipment: Oil Filter Machine >>) Soybean Oil Refining Process

Soybean Oil Refinery Machine

- Raw Material: soybean

- Production capacity: 1-500T/D

- Power ( W): 10-50kw

- Voltage:220V/380V

- Dimension (L*W*H )):46*32*12m

- Weight:30 tons

A soybean oil refinery machine is used to purify and refine crude soybean oil extracted from soybeans, removing impurities such as free fatty acids, phospholipids, pigments, and other undesirable elements. The refining process results in high-quality, edible soybean oil suitable for cooking, baking, frying, and other food products.

Discover high-efficiency edible oil refinery machines designed for optimal oil purification and processing. Suitable for various oils like soybean, sunflower, palm, and peanut, these machines ensure premium quality oil with advanced refining technology. Enhance your production with our durable and cost-effective solutions.