SOYBEAN GRINDING - Bauermeister Size Reduction Equipment

- Type: soybean oil machine

- Usage/Application: soybean

- Production capacity: 1-800T/D

- Voltage: 380v-440v

- Weight: different

- Dimension (L*W*H): different

- Power (W) : 10-50kw

- Country: lagos

HOME > APPLICATIONS > FOOD > SOYBEAN GRINDING Soybean GrindingSoybeans are, next to rape and sunflower seeds in Europe and palm fruit in Asia, one of the largest sources of industrial cooking oils. However, besides being an oil seed, soybeans are often also used to win fibers and proteins. Depending on the intended use different fractions of

Soybean Grinding Machine - Bean Grinder, Soybean Grinder

- Type: soybean oil processing machine

- Production capacity: 50-1000 kg/h

- Voltage: AC 220 V, 50 Hz

- Main components: Engine oil

- Weight: 240 kg

- Dimension (length x width x height): 700/800 /780 mm

Bean Grinder, Soybean Grinder, Automatic Bean Grinder, Soymilk Grinding Unit, Stainless Steel Grinder. The Soybean Grinding Machine adopts an open-type grinding stone design, the grinding stone is easy to be replaced, the vibration is small, quiet and high stability during operation, so that the soy milk has good fluidity and no residue, easy to clean, saves washing time, and meets hygienic

Soybean milling is the process of taking whole soybeans and processing them into a usable product: soybean meal. Processing soybeans typically involves de-hulling soybeans and then crushing or cracking them so they can be used for a wide range of applications. Although soybean milling is a common practice, not every milling method is optimal.

Oilseed Processing | Oilseed Preparation | Bühler Group

- Usage: soybean oil

- Production capacity: high

- Voltage: 220V, 380V or other

- Weight: depends on capacity

- Dimension (L*W* H): depends on capacity

- Power (W): depends on capacity

We offer processes and technologies for the grinding and pelleting of extraction meal to help you get more value out of your by-products. Hull grinding & pelleting solutions Separated sunflower and soybean hulls have half the thermal value of heating oil and can be used as an alternative energy or heating source.

High-capacity machines like soybean crushers and soybean milling machines are ideal for large plants, while smaller units can suit smaller operations. 2. End Product. Select machines based on the type of product you want to produce. For oil production, soybean press machines or soybean extractors are ideal.

SOYBEAN PROCESSING EQUIPMENT - bronto

- Type: cooking oil extraction machine

- Production capacity: 60%-70%

- Voltage: 220v/380v

- Core Components: Pump

- Weight: 565KG, 565kg

- Dimension (L*W*H): 1650*1500*1600mm

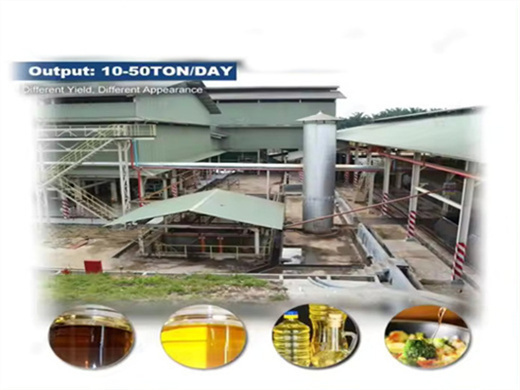

production of soybean oil . The processing line copes with the following processes: soybeans dehulling or decortication, soy grinding, mixing and heating up due to high pressure, high shear and temperature, decreasing of trypsin inhibitor and urease activity, pressing out the oil from the full fat soybean.

Choose our Soybean Grinders and experience the exceptional performance and durability they offer. Our machines are designed to meet the demands of high-volume soybean grinding in commercial settings. With their powerful motors, efficient grinding capabilities, and versatile features, you can rely on our brand to enhance your soy-based product

high quality hydraulic soybean oil press machine lagos

- Raw Material: soybean

- Production capacity: 500 units daily

- Dimension (L*W*H): 43*31* 47CM

- Voltage: 220 V, 220 V/50 HZ

- Weight: 9 KG

- Warranty: 1 year

Hydraulic Oil Press | Oil Extractor - Taizy. The automatic hydraulic oil press is a small oil press with simple operation, high oil yield, and fewer wearing parts than the mechanical oil press. It is an advanced oil press equipment that replaces the small grinding of sesame oil manually. The whole machine is mainly composed of three parts: 1

The soybean contains 18 – 20 % oil content. After a single stage pressing, about 5 – 5.50% residual oil in the soybean meal which will be used in animal & poultry feed. Soybean oil expeller mainly uses the change of screw pitch size and screw thread deep to reduce the volume between the screw pitch and the pressing chamber, the raw material