FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 100kg/h-1000kg/h

- Voltage: 220V/380V

- Main components: Pressure container

- Weight: 50 KG

- Dimension (L*W*H): 1700*1100* 1600 mm

- Country: pakistan

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a mill commonly handles 2.5 to 150 MT per hour of FFB. The quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the FFBs and the process adopted. A palm oil mill produces crude palm oil and kernels as primary

FFB Fresh Fruit Palm Oil Press Production Line CPO

- Type: palm oil processing machine

- Production capacity: 15~20 tons/day

- Voltage: 220V/380V/440/415V

- Full Oil Warranty Service: Video Technical Support

- Weight: 0 KG

- Dimension (length x width x height) : 8.8 x 4.7 x 12.2 ft

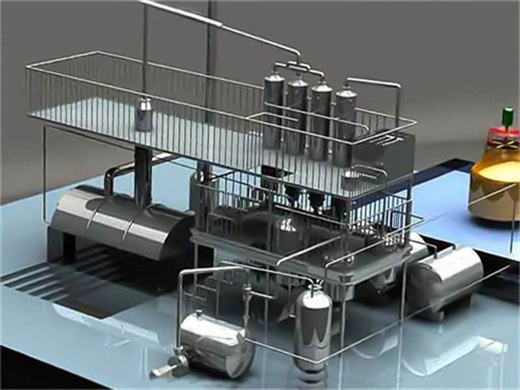

FFB Fresh Fruit Palm Oil Press Production Line CPO Section Introduction: We can offer turnkey palm oil press plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing Our palm fruit oil processing plant capacity range from 3t h to 100t h with automatic palm oil mill control system

Palm Oil Mill process is quite different from other vegetable oil seeds processing. Palm fruits consists a lot of fatty acid enzyme, which would hydrolyze palm oil. That’s the reason why palm fruit must be sent into processing in 24 hours. At the Palm oil mill, the main products that are produced from FFB to Crude Palm Oil (CPO) and Palm Kernels.

Complete Palm Oil Production Line

- Usage: palm oil

- Customized: Customized

- Applicable: Industrial Food and Beverage Farm Manufacturing

- Advantage: Energy saving

- Maximum capacity: 80 kg/H

- Weight: 280 kg

Palm Fruit Pretreatment and Oil Press: 1. Palm Fruit Reception: Firstly, transport FFB to reception station, flow to the scraper conveyer, conveyed to sterilizing station. 2. Sterilizaiton: FFB transported by scraper conveyer fall into Sterilizing Tank, make FFB soft to get more oil yield. The sterilizing time is 90~120mins and temperature 130

This 500 kg/h Fresh Fruit Palm Oil Mill is a compact and efficient solution for small-scale palm oil production. Designed for farms, cooperatives, and small oil processing businesses, this mill provides a complete solution to extract crude palm oil from fresh fruit bunches (FFBs) with minimal labor and time investment.

FFB Oil Palm into CPO (Crude Palm Oil) Oil Mill Plant

- Type: cooking oil extraction machine

- Production capacity: 50-1000 t/d depends on your request

- Power (W): As Capacity of the solvent extraction plant

- Voltage: 380 V

- Dimension (L*W*H): As per request of the solvent extraction plant

- Weight: As output from solvent extraction plant

Complete FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil) Threshing & Extraction Processing & Refining & Fractionation Machinery and Solution with Full Around Technology and Service! Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a mill commonly handles 2.5 to 150 MT per hour of FFB.

Now palm oil mill/from fresh palm fruit bunch(FFB)to crude palm oil machine like 1tph, 2tph , 3tph are very popular in Africa. What I am sure is our design is unique and based on our engineer's long time practice experience and we helped many African clients and south Asia clients to set up good palm oil mill plant projects.

Palm Oil Mill Plant Production Line - Hongde OIL MACHINE

- Raw Material: palm

- Production capacity: 20~2000T/D

- Power (W) : up to specification

- Voltage: 380v/50Hz

- Dimension (L*W) *H): 1360*950*1170mm

- Weight: as per specification

Our palm fruit oil processing plant capacity ranges from 3tph to 120tph. Welcome to contact us. Complete palm oil production process in a large-scale palm oil factory. Fresh fruit bunches (FFB) of oil palm after the fruit is harvested, it is processed in a palm oil mill, where the FFB is sterilized, digested, and pressed to extract palm oil.

Palm oil mill process of purification: oil purification process to improve palm oil purity. Palm oil mill process of drying: continuous Vacuum drier with the oil out of the water, the water can be reduced to 0.1%. 8. Palm oil mill process of depericarper (splitter): through floating dry processing the fruit core and fibers separated. Fiber