easy to use palm oil processing plant in zimbabwe

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Voltage: 220v

- Dimension (L*W*H): 46*18*34cm

- Oil type: Cooking oil

- Main components : Motor

- Weight: 12KG

- Country: zimbabwe

We are a professional Palm Oil Processing Machine manufacturer. We can provide palm oil pressing machine, small and large scale palm oil processing plant, automatic palm oil mill plant, Palm Oil Refinery machine and palm oil fractionation plant.

How a Small Palm Oil Mill Plant is Set Up?

- Type: palm oil processing machine

- Production capacity: 100-6000 kg/h

- Voltage: 220v/110v

- Main components: Motor, PLC, Others, Gears

- Weight: 9.5 KG

- Dimension (L*W*H): 390*150*292mm

An interesting thing about the global palm oil market is that it needs mini and small palm oil mill plants in order for its marketing operations to be successful. Normally, a mini scale plant usually produces between 1-10 tonnes of palm oil daily while a small scale plant can process between 10-20 tonnes per day.

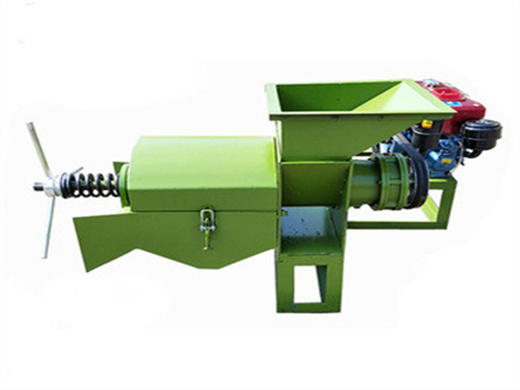

They are known for their durability and ability to extract high-quality oil with minimal waste. (1)Small palm oil srew press. This is a 500kg/h palm oil press machine, suitable for home use, small investors and palm oil production line business starters, and it is simple to operate. Single screw palm oil press machines (2)Double screw oil press

Small Scale Palm Oil Mill Plant, Equipmentfor 1-20t/d Production

- Usage: palm oil

- Production capacity: 80-800kg/h-99%

- Voltage: 380v

- Main components: bearing, gearbox

- Weight: 1900KG

- Dimension (L*W*H): 2.65m*1. 9m*2.7m

One is mini palm oil mill plant for 1~10 ton/day factory, and the other one is 10~20 ton/day palm oil milling plant for small and medium-sized factory. Main Processing Equipments for Crude Palm Oil Mill Plant. The main equipment for small palm oil mill is palm fruits cooking and sterilizing tank, FFB Stripper and screw palm oil press machine

For the single-machine plants required in a small scale palm oil processing plant, if your palm plantation covers an area of 110 hectares, we recommend our 500kg/h single screw palm oil press to you, whose screw is made of wear-resistant alloy steel and one-piece casting process, which is not only of good quality but also very wear-resistant.

Palm oil press machine_Palm Oil Processing Plant

- Type: cooking oil extraction machine

- Production capacity: 30-40 kg/h / 400-500 kg/h

- Dimension (L*W*H) ) : 1360*950*1170mm

- Voltage: 380 V

- Weight: 290 KG

- Main components: motor, PLC, gear, motor, gearbox

300-500kg/h mini single screw palm oil press machine. Single screw palm oil press machine. 300-500kg/h mini single screw palm oil press machine is suitable for farmer use or small palm oil mill use. It is not only low cost, small footprint, easy operation, but also high efficiency. The parameter of 300-500kg/h mini single screw palm oil press

There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant due to its high oil extraction rate.

Small Palm Oil Refining Equipment for 1-30 ton/day Processing

- Raw Material: palm

- Production capacity: 100-1000 kg/h

- Dimension (length x width x height): 1900*680*1440

- Voltage: 380V

- Weight: 140 KG

- Main components: Motor, Gear, bearing

The central nut or kernel can be separated and applied for extracting palm kernel oil. Palm Kernel Oil: The palm kernel getting from the extraction of palm oil will be collected for making palm kernel oil. Palm kernel expeller or cake is the main by-product of palm kernel processing line. Refining Process of Crude Palm Oil (3 Types)

Before making your business plan for starting a palm oil extraction factory, it is important to learn about the palm oil mill process. The process of palm oil extraction is very different from the processing of other seeds. Gnerally, palm oil mill includes 6 processes: fruits reciving, cooking/sterilizing, threshing, digesting, oil pressing, crude oil clarification, refining and fractionation, and pal kernel recovery.