Palm Oil Pressing Machine

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 5TPD-100TPD

- Voltage: 220V/50HZ three-phase

- Warranty: 1 year, 1 year

- Weight: 27.1 KG

- Dimension (L*W*H) : 1055 *805*345mm

- Country: lagos

With more than 200 patented technologies as the core, Hongde Oil Machinery has overcome the high oil loss and high energy consumption problems in palm oil processing – from fresh fruit (FFB) sterilization and pressing to crude palm oil (CPO) refining and fractionation, the oil output rate of our palm oil equipment leads the industry by 5%-10%

Palm Oil Machine - Palm Oil Production Line

- Type: palm oil processing machine

- purpose: cooking oil mill machine

- Description: high oil yield

- smell: original cooking oil flavor

- color: fresh and bright

- Material: steel stainless or carbon steel

Palm Oil Machine. Henan Hongde Cereals and Oils Machinery Co., Ltd. has been focusing on the research and development and manufacturing of palm oil processing machine for more than 37 years, providing a full set of solutions from palm fruit pressing to palm oil refining.

High Efficiency: Our Palm Oil Press Machine utilizes the optimized palm fruit pressing technology to maximize oil extraction while minimizing waste and residual oil. Cost-Effective: The Palm Oil Press Machine’s low energy consumption and minimal maintenance costs make it a highly cost-effective solution for palm oil production.

Hongde palm oil machine / FFB oil mill - Palm Oil Production Line

- Usage: palm oil

- Automatic grade: Semi-automatic

- Production capacity:1-500T/D

- Dimension (L*W*H):1910*550*765 mm

- Power (W): 7.5kw

- Voltage:220V/380V

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

Henan patented palm fruit oil press, with a processing capacity of 2-20TPH, this series of products is fully automatic controlled by PLC, and the hydraulic system controls the cake discharge, which can effectively reduce the residual oil and nuclear breakage rate in the cake, and the spiral body and press cage are used with high strength.

palm oil making machine/crude palm oil production lagos

- Type: cooking oil extraction machine

- Production capacity: 98%

- Voltage: 220V/380V/440V

- Weight: 1050 KG

- Dimension (L*W*H): 430*230*350

- Power (W): 10-50kw

Improving Sustainability of Palm Oil Production. Empty Fruit BunchesPalm Press FibresOil Recovery from Palm Oil Mill EffluentTypically, a palm oil mill produces around 22 to 27% of EFB with respect to FFB (Aziz et al. 2015; Kramanandita et al. 2014; Mamat et al. 2017). EFB normally contain about 0.5% (wrt FFB) of residual oil.

Palm Oil Mill Design. Specialized in designing and constructing large scale palm oil milling plant including all machines to manufacture palm oil to international standards. The capacity ranges from 3 tonnes to 60 tonnes of FFBs per hour. Our palm oil mill projects are designed with mechanical handling systems including pipelines, pumps, screw

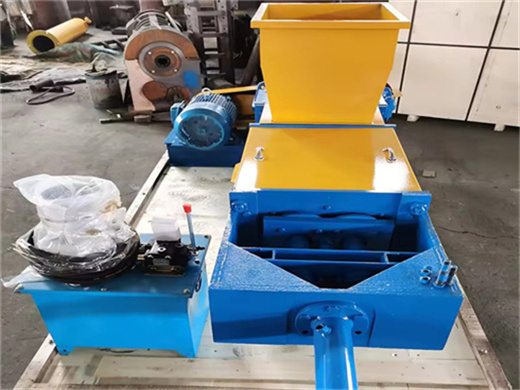

Screw Palm Oil Press Machine, Oil Pressing Plant for Sale

- Raw Material: palm

- Production capacity: 50-500kg/h.

- Dimension(L*W*H): 52.5x24.5x30cm

- Voltage: 110V/180v-240v/50-60HZ

- Weight: 12 KG

- Main components: Motor

In pressing stage, mechanical screw palm oil pressing machine is used to extract the oil out of digested palm pulp which is a mixture of oil, water, fibre and nuts. Hydraulic presses and the older centrifuges have been deemed almost redundant today as palm oil processing plants these days use specifically designed screw-presses much like the

Before making your business plan for starting a palm oil extraction factory, it is important to learn about the palm oil mill process. The process of palm oil extraction is very different from the processing of other seeds. Gnerally, palm oil mill includes 6 processes: fruits reciving, cooking/sterilizing, threshing, digesting, oil pressing, crude oil clarification, refining and fractionation, and pal kernel recovery.