palm oil processing equipment and supplies jambi

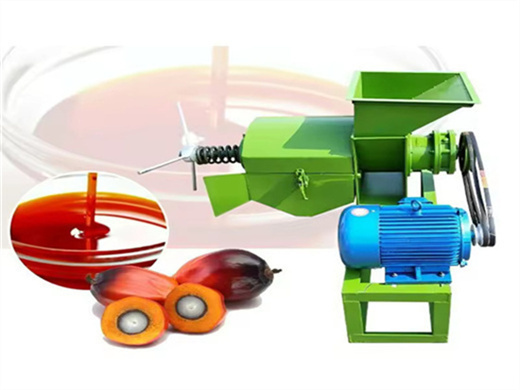

- Type: palm oil equipment

- Usage/Application: palm fruit, palm kernel

- Production capacity: 95-100%

- Voltage: 380 V

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox, other

- Weight: 1750 KG

- Dimension (L*W*H): 2500*1500*1800 mm

- Country: lagos

How do palm oil mills work? Ten of our mills are powered by biogas power plants that convert leftover organic material from the palm oil production process into renewable energy. Located in North Sumatra, Riau, and Jambi, these power plants supply electricity to the surrounding communities in addition to our mills. What is palm oil […]

Palm oil milling equipment and machinery | | Alfa Laval

- Type: palm oil processing machine

- Weight: 50 KG

- Main components: Motor, pressure vessel, pump

- Filter press type: Automatic filtration machine

- Name of the product: Stainless steel oil filter press

- Oil type: Cooking oil

For decades, Alfa Laval has worked closely with palm oil mills in the development of reliable, efficient solutions for converting palm fruit into crude oil. Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack centrifuges optimized for mills, as well as

Above listed all the palm oil production equipment needed for palm oil processing. In actual condition, the equipment selection is closely related to capacity, process, budget, etc. If you have no ideas about how to choose the suitable machines for your palm oil processing factory. Please seek advices from professionals, don't make decision easily.

Hongde palm oil machine / FFB oil mill - Palm Oil Production Line

- Usage: palm oil

- Production capacity: 150-250 kg/h

- Voltage: 220V/380V

- Vacuum pump: Y90S-4-1.1KW

- Dimension (L*W*H): 1950*1300*1900mm

- Power: 12kw

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce industrial oil or cosmetic raw materials, the oil can also be separated by distillation equipment according to different melting points.

Palm oil processing and production process | Alfa Laval

- Type: cooking oil extraction machine

- Key Selling Points: High Precision

- Outgoing Video Inspection: Provided

- Marketing Machinery Test Report: Provided

- Warranty of main components: 1 year

- Main components: PLC

A full range of palm oil milling equipment, with everything you need for your oil room and (crude palm oil) CPO washing; Reliable palm oil refining process technologies with complete plant solutions for bleaching and deodorizing; Advancements to improve end-product quality while simultaneously boosting capacity, limiting loss and increasing yield

Palm oil extraction & palm kernel oil extraction & palm oil refining. As we all know, oil palm can produce two kind of oils - palm oil extracted from fresh fruit and palm kernel oil obtained from the nuts. Next you will learn about the palm oil processing process and palm kernel oil processing process. Read More>>

Small Scale Palm Oil Mill Plant, Equipmentfor 1-20t/d Production

- Raw Material: palm

- Production capacity: 160-200 kg/h

- Dimension (L*W*H): 1910*610* 765

- Voltage: 220 V/380 V

- Weight: 420kg

- Warranty: 1 year, one year

The main equipment for small palm oil mill is palm fruits cooking and sterilizing tank, FFB Stripper and screw palm oil press machine. Click the link to see more details of the related palm processing machines. Small Scale Crude Palm Oil Milling Process. The main processing flow includes Palm Fruits, Threshing, Digesting, Pressing and Filtering.

Palm oil mil process of purification: oil purification process to improve palm oil purity. Palm oil mil process of drying: continuous Vacuum drier with the oil out of the water, the water can be reduced to 0.1%. 9.Palm oil mil process of depericarper (splitter): through floating dry processing the fruit core and fibers separated. Fiber