Palm Oil Refining Machine - Palm Oil Production Line

- Type: palm oil production line machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 20~2000T/D

- Voltage: 380v/50Hz

- Function: tea seed oil machine

- Dimension (L*W*H) : 2050*1350*2000Weight: 1000kg

- Power ( W): 7.5kw

- Country: lesotho

Palm Oil Refinery is the main oil machinery and equipment to ensure the quality, grade and edible safety of oil in the palm oil processing process. The palm oil refining machine produced by Henan Huatai Cereals and Oils Machinery Co., Ltd. can flexibly adapt to different production needs with advanced technology and modular design:

Palm Oil Mill Plant Production Line - HUATAI OIL MACHINE

- Type: palm oil refinery machine

- Production capacity: 1t/day-1t/hour

- Voltage: 220V

- Main components: motor, others

- Weight: 12 KG, 12 kgs

- Dimension (L*W*H): 46*18*34 cm

The six processes of palm oil refining machine. palm oil refining equipment to remove harmful substances at the same time, but also better preservation of oil in the Vitamin A and Vitamin E and other nutrients, to improve the quality of palm oil. 2024-08-07

Huatai Oil Machinery is a leading company in the field of palm oil pressing and palm kernel oil processing and equipment, we can provide completely set of 5-120tph palm oil production line. Our company offers a range of products and services for the palm oil extraction, palm kernel oil extraction, crude palm oil refining and complete palm oil

Huatai palm oil machine / FFB oil mill - Palm Oil Production Line

- Usage: palm oil

- Production capacity: 5-500 TPD

- Voltage: 440 V

- After-sales service provided: Engineers available to service machinery abroad.

- Certification: ISO,CE

- Weight: 500 TONS

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Huatai palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

Huatai oil machinery can provide a whole palm fruit/palm kernel oil mill plant production line for you, if you have a lot of palm fruit to process, you can contact with us. We can offer you a whole line of palm oil pretreatment equipment, palm oil extraction machines, and palm oil refinery machines, and build a palm oil turnkey project from A

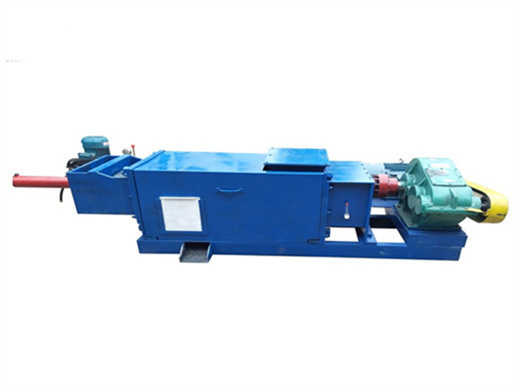

Palm Oil Processing Production Line

- Type: cooking oil refining machine

- purpose: oilseed press oil machine price

- residual oil: less than 6%

- Description: high oil yield

- color: bright fresh

- smell: original Niger seed oil

Palm oil fractionation equipment can separate palm oil into soft fat and hard fat by controlling the cooling and crystallization process of palm oil. The melting point of hard fat is 50°C and the melting point of soft fat is 24°C. There are three common palm oil fractionation temperatures: 18°C, 24°C, and 36°C.

The Batch type is the ideal choice for small-sized palm oil production (1-20TPD), while the Semi-continuous Refinery plants are the best choices for middle-large size production lines (20-50TPD), a fully continuous refinery line(50-600TPD) is most used in large palm oil production plants.

palm oil line

- Raw Material: palm

- Production capacity: 1t/day-1t/hour-100%

- Weight: 180 KG

- Voltage: 220V/380V/440V

- Main components: Motor

- Oil type: Cooking oil

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce industrial oil or cosmetic raw materials, the oil can also be separated by distillation equipment according to different melting points.