Mechanical Methods of Oil Extraction from Peanuts

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Main components: PLC, bearing, motor, pressure vessel, gear, pump

- Voltage: 415V ± 10%, three-phase, AC

- Coating type: Heating and coating

- Weight (KG): 200

- Dimension (length * width * height): 1520 x 1145 x 1755 mm

- Country: nairobi

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

Various methods for extracting oil from groundnut

- Type: peanut oil processing machine

- Production capacity: 40-600kg/h

- Voltage: 110/220v

- Main components: Motor

- Weight: 8 KG

- Dimension (L*W*H): 45*30*22cm

The only difference is that the groundnut oil press production line need to be worked with groundnut oil solvent extraction plant. Groundnut oil pre-pressing machine can extract most of groundnut oil, the groundnut oil solvent extraction plant can recover almost all the oils and leaves behind only 0.7% to 1% residual oil in the raw material. In

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Usage: peanut oil

- Dimension (L*W*H): 2320*1500*1170 mm

- Weight: 600 KG

- Outgoing video inspection: Provided

- Marketing machinery test report: provided

- Key selling points: Automatic

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

The dry meal will be packaged for sale as animal feed. Usually, by using the peanut oil extraction method, the residual oil in the cake will be less than 1%. But different with peanut oil pressing method is that peanut oil obtained by solvent extraction method must be refined before it can be eaten.

Peanuts Mechanical Methods of Oil Extraction from

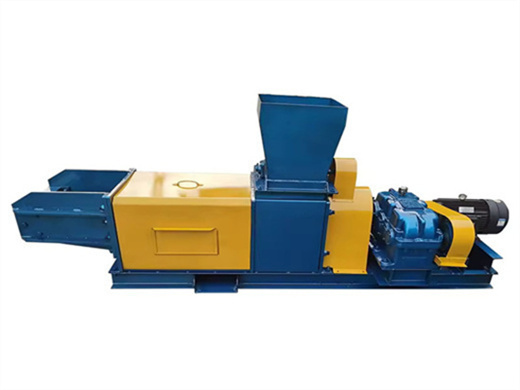

- Type: cooking oil extraction machine

- Production capacity: 150-300 kg/h

- Voltage: 220v 380v

- Main components: Motor, PLC

- Weight: 1100kg

- Dimension (length x width x height): 2000*1500*1700MM

techniques for oil extraction from peanuts are grouped into three main sections: extrusion and screw pressing, cold pressing, and hydraulic pressing. oil extraction mechanical methods defatting peanuts defatted peanuts peanut proteins texturization MEPSI 1. Introduction Peanut, or

extraction of oil from groundnuts. In the present study celluclast 1.5L was used for the pre-treatment. The effect of enzyme concentration (5-10%), temperature (50-60⁰C), pH (5.0-6.0), reaction time (1-7 h) on free oil liberated was studied. Residual oil was collected by subjecting the treated meal to soxhlet extraction for 4 h.

What is the basic principle of peanut oil solvent extraction?

- Raw Material: peanut

- Production capacity: 50-1000 kg/h

- Dimension (L*W*H): according to capacity

- Voltage: 380 V

- Weight: 60000 KG

- Main components warranty: 5 years

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

Peanut oil, also known as groundnut oil or arachide/arachis oil, is a mild-tasting vegetable oil derived from peanuts. The oil is available with a strong peanut flavor and aroma, analogous to sesame oil. Groundnut (Arachishypogaea) contain up to 50% oil (although the usual range is 40% to 45%). ITDG (2011).