(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 3-4 kg/h

- Voltage: 220v

- Function: Manufacture edible oil

- Weight: 6.6 kg

- Dimension (L*W*H): 320*150*350mm

- Country: zimbabwe

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques

Peanut Oil Processing Technology - ScienceDirect

- Type: peanut oil processing machine

- Voltage: 380V

- Use for: Various Seeds, Sunflower

- Color: Customer request

- Power: 380V, 50Hz, Three-phase

- Capacity: 40kg, 200kg, 300kg , 500kg

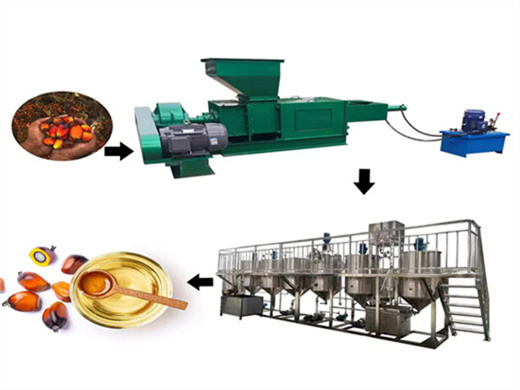

It starts by explaining the pretreatment technology and peanut pressing technology of high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology. At the end of the chapter, it discusses the peanut oil production line and the relevant key equipment.

Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent (n-hexane) extraction [29]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

The Indonesian Journal of Computer Science - ijcs.net

- Usage: peanut oil

- Production capacity: 150-250 kg/h

- Voltage: 380V

- Weight: 950 kg

- Dimension (L*W*H): 1950x1300x1900

- Power (W): 7.5Kw

of revenues and expenses by using the payback period method. [6]. B. Peanut Oil Production Process The peanut oil production process involves machines that are developed to carry out sub-processing operations involved in traditional peanut oil extraction. These machines are; shelling, grading, drying, and pressing [1].

A study carried out in 2019 by Suri et al. examined how peanut oil quality characteristics were affected by a combination of dry air roasting and mechanical extraction using screw pressing . The researchers found that optimal conditions for air roasting were 180 °C for 10 min, followed by cooling at room temperature.

What are the common extraction methods of extracting peanut

- Type: cooking oil extraction machine

- Production capacity: 100TPD

- Voltage: 220V/380V

- Main components: motor, pump, PLC, cooking oil press machine

- Weight: 250kg

- Dimension (L*W*H): 400*500*850mm

The dry meal will be packaged for sale as animal feed. Usually, by using the peanut oil extraction method, the residual oil in the cake will be less than 1%. But different with peanut oil pressing method is that peanut oil obtained by solvent extraction method must be refined before it can be eaten.

M e cha nica l M e tho ds o f Oil Ex tra ctio n f ro m P e a nuts | Ency clo pe dia . pub https: / / e ncy clo pe dia . pub/ e ntry / 48924 1/ 14 Mechanical Methods of Oil Extraction from Peanuts Subjects: Engineering, Industrial Contributor: Freddy Mahfoud , Jean Claude Assaf , Rudolph Elias , Espérance Debs , Nicolas Louka

peanut oil production machine and equipment in zimbabwe

- Raw Material: peanut

- Production capacity: 2.2kw

- Dimension (L*W*H): 1200*1000*1100mm

- Voltage: 220v/380v/customized

- Weight: 268 KG

- Main components: Others

Groundnut oil is in very high in demand in international market, so establishing a groundnut oil processing mill for business purpose is considering as a financially profitable idea for those who want to set up a business in the edible oil production line industry. So if you are interesting about starting a groundnut oil mil business plan, here is a complete business plan of a small scale groundnut oil processing mill. It will be very useful to take these guidances into consideration when starting. (You may also interested in the groundnut oil processing plant setup cost in Africa countries)

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.