how to extract groundnut oil | Supply of turnkey project for

- Type: peanut oil project

- Usage/Application: peanut, groundnut

- Production capacity: 100TPD

- Voltage: 220V/380V

- Weight: According to the capacity of palm screw oil pressing machine

- Dimension (L*W*H): 1200*400*900mm3

- Power (W): According to palm Capacity of screw oil pressing machine

- Country: tanzania

In the production process of groundnut oil processing plant, oil refining processes are particularly important. Peanut oil refining equipment is a device that can process many impurities in crude oil. The presence of impurities in the crude oil not only affects the edible value and safe storage of oil, but also brings difficulties to deep processing. Using peanut oil refining equipment for oil refining, it will not remove all the impurities in crude oil, but rather removes the impurities contained therein that are harmful to food, storage, and human health. For example: protein, phospholipid, moisture, etc.

What are the common extraction methods of extracting peanut

- Type: peanut oil processing machine

- Material: carbon steel or stainless steel

- Capacity: 5-600T/D raw cooking oil processing plant

- Raw material: Vegetable Seed

- Packaging: according to customer requirements

- Certification: CE and ISO

The dry meal will be packaged for sale as animal feed. Usually, by using the peanut oil extraction method, the residual oil in the cake will be less than 1%. But different with peanut oil pressing method is that peanut oil obtained by solvent extraction method must be refined before it can be eaten.

Beyond extraction, we’ll also talk about the machines you need to prepare your feedstock and refine the crude oil that you extract. Let’s dive right in. Peanut oil manufacturing: Raw material Peanut oil is made from peanuts, also called groundnuts (scientific name Arachis hypogaea). They are a preferred raw material to make edible oil

What is the basic principle of peanut oil solvent extraction?

- Usage: peanut oil

- Production capacity: 98%

- Voltage: 220V/380V/440V/Customer requires

- Warranty: 1 year

- Weight: 3000 KG

- Dimension (L*W*H): According to capacity

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

Mechanical Methods of Oil Extraction from Peanuts

- Type: cooking oil extraction machine

- Production capacity: 100 TPD

- Dimension (L*W*H): 4875t1828t1985

- Voltage: 170 HP

- Weight: 14000 KG

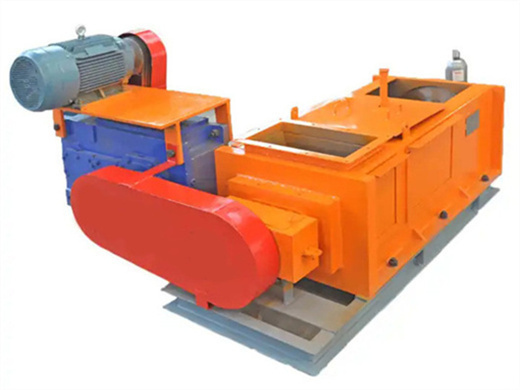

- Main components: motor, bearing, gearbox

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

Therefore, it is essential to equip the peanut oil production plant with professional edible oil refinery equipment to get them off and obtain the refined high-quality peanut oil. Groundnut Oil Processing Flowchart. Cost of Groundnut oil extraction machine: Generally, the cost of Groundnut oil extraction machine will be approximately Rs 1.8

Peanut Oil Extraction - LinkedIn

- Raw Material: peanut

- Product type:Other

- Cultivation type:COMMON

- Processing type:Cold pressed

- Use:Cooking

- Packaging:Can (canned), Drum, Plastic Bottle

Solvent extraction is a more advanced method used to extract peanut oil, particularly when high oil yield is desired. This method involves the use of chemical solvents to dissolve the oil from the

The pre press press process requires only about 70% of the oil press material is pressed cake of residual oil in 15% ~ 18%, pre pressing cake and solvent oil. Oil press oil extraction and other oil extraction method compared with simple process, less equipment, facilities for oil production, strong adaptability, flexible oil quality, light