(PDF) Defatting and Defatted Peanuts: A Critical Review on

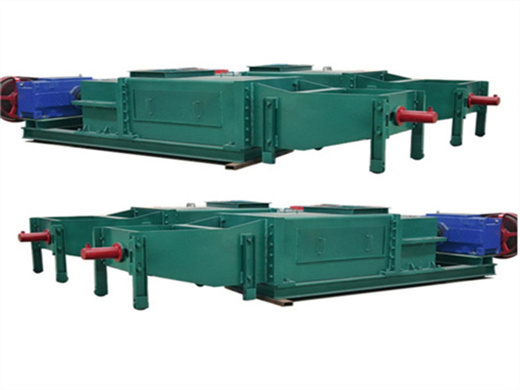

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 20 ton/day

- Voltage: 380V/440V

- Warranty: One year warranty against manufacturer defects.

- Weight: 0 KG

- Dimension (L*W*H): 11.48*4.26*11.81 feet

- Country: bangladesh

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques

Peanut Oil Processing Technology - ScienceDirect

- Type: peanut oil processing machine

- Voltage: 220 V/380 V

- Power (W): 18.5 kW

- Certification: ISO9001

- Weight: 2000kg

- Dimension (L*W*H): 1500*1600*2500mm

The leaching procedure mainly makes use of the solid-liquid extraction principle to select certain fat-dissolving organic solvents to extract the peanut oil. Generally speaking, the leaching solvent should meet the following conditions: good fat solubility, stable physiochemical properties, easy separation from the fat and meal, and be safe

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Usage: peanut oil

- Production capacity: 100% oil refining equipment

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L*W*H): Depends on its capacity

- Power (W): 10-50kw

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

processing most widely used is the peanut oil. The peanut cake or meal obtained after oil extraction which can be full fatted, partially defatted or defatted is later used as flour, isolates and concentrates [6]. Oil extraction from the peanut kernel is a well-established industrial since the early 1950s. They have thus supported in

Groundnut Oil Production Process: From Farm to Bottle

- Type: cooking oil extraction machine

- Main components: biomass boiler generator

- Pressure: High pressure

- Structure: Water tube

- Steam production: 0. 5 t/h

- Style: Horizontal

The remaining oil is then extracted using the solvent extraction method. If using mechanical pressing technology, the oil production process consists of three key stages: preparation of peanuts, pressing, and refining of crude oil. The overall extraction process involves five steps: cleaning, dehulling, cooking, pressing, and filtering.

M e cha nica l M e tho ds o f Oil Ex tra ctio n f ro m P e a nuts | Ency clo pe dia . pub https: / / e ncy clo pe dia . pub/ e ntry / 48924 1/ 14 Mechanical Methods of Oil Extraction from Peanuts Subjects: Engineering, Industrial Contributor: Freddy Mahfoud , Jean Claude Assaf , Rudolph Elias , Espérance Debs , Nicolas Louka

Extraction of Edible Oil From Groundnut By using Solvents

- Raw Material: peanut

- Production capacity: According to your capacity

- Power (W): According to your requirement

- Voltage: According to your requirement

- Dimension (L*W) *H): According to your requirement

- Weight: According to your requirement

extraction of oil from groundnuts. In the present study celluclast 1.5L was used for the pre-treatment. The effect of enzyme concentration (5-10%), temperature (50-60⁰C), pH (5.0-6.0), reaction time (1-7 h) on free oil liberated was studied. Residual oil was collected by subjecting the treated meal to soxhlet extraction for 4 h.

pressed peanut oil preparation, were roasted under 150 °Cfor 75 min, and also pressed in a hydraulic pressure machine (Tianjin JudaMachineryManufacturingCo.Ltd.)withpressuresetat100–