Peanut oil processing ppt - edible oil extraction machine

- Type: peanut oil press

- Usage/Application: peanut, groundnut

- Certification: ISO, BV, CE, CE, ISO9001, BV, etc...

- Product type: cooking oil mill processing

- Residual oil in flour : ≤ 1%

- keyword: cooking oil productions

- Power: as required

- Country: lusaka

Henan Doing Company is a professional world-wide cooking oil processing machine supplier. Next let us see the peanut oil processing ppt to learn the whole peanut oil processing process. Peanut oil processing machine. The whole peanut oil processing machine contains three workshops: 1. Peanut oil pretreatment and pre-pressing workshop;

Peanut/Groundnuts Oil Processing | Hot & Cold Press

- Type: peanut oil processing machine

- Production capacity: 5TPD

- Voltage: 110v/220v/380v

- Main components: Bearing, motor, gearbox

- Weight: 800 KG

- Dimension (L*W*H): 2100*900*1800mm

Peanut oil is light yellow and transparent, bright in color, fragrant in odor, and delicious in taste, and is an edible oil that is relatively easy to digest. Peanut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid). It also contains 19.9% saturated fatty acids such as limonoic acid, stearic

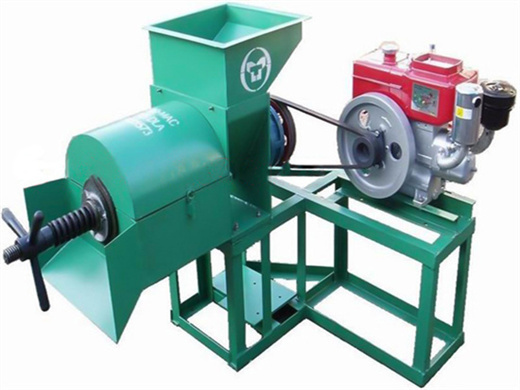

Our products range from small peanut oil presses to large industrial peanut oil production lines to meet the needs of customers of different sizes. The main equipment includes peanut pretreatment equipment (cleaning machine, shelling machine, flaking machine, etc.), peanut oil presses, peanut oil refining equipment and related auxiliary equipment.

What machines are needed to produce peanut oil by pressing

- Usage: peanut oil

- Form: Oil

- Variety: Hemp seed

- Grade: Therapeutic grade, Superior grade

- Extraction packaging: Bottle, Drum, Glass container, Plastic container

- Part: Seed

The peanut roasting process can make it reach the best situation. After that, we can send the prepared peanuts to the peanut oil press machine to squeeze out peanut oil. Peanut oil production machine. Pressing: In the process of peanut pretreatment and pressing, the oil residue in the peanut cake after pressing is about 7%. The peanut cake

Automatic peanut oil press machine is a kind of superior oil pressing machine nowadays in the market. It is used for processing cooking oil from various oil bearing materials such as peanuts, soybeans, sunflower seeds, rapeseeds, oil palm, sesame seeds and so on. This peanut oil extraction machine is an integrated oil press machine and suitable

Fragrant Peanut Oil Press Machine - Oil Pretreatment

- Type: cooking oil extraction machine

- Production capacity: 200 kg/h

- Power: 7.5KW

- Voltage: 380 V

- Dimension (L*W*H): 1300*700*1000MM

- Weight: 500kg

The adoption of screw oil press machine keeps press temperature of 135 ℃, moisture of 1.5% to 2%, peanut press cake residual of 9% to 10%.Crude peanut oil after precipitation and vertical leaf filter filtration is sent to peanut oil refining plant. Peanut oil cake after oil press process is sent to oil extraction plant for secondary extraction.

Peanut Oil Pressing Methods. Generally, the husk content of peanut is 30-35%, and the oil content in peanut kernel is 40-50%. Therefore, the peanut pretreatment processes include cleaning, dehusking and separating of hull & kernels. According to pressing temperature, there are two peanut oil pressing technologies: hot pressing and cold pressing.

What is the peanut oil pressing process?__Vegetable oil

- Raw Material: peanut

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): depends on the model

- Voltage: 220V/380V

- Weight: 140--350KG

- Warranty: 1 year, 1 year

The peanut roasting process can make it reach the best situation. After that, we can send the prepared peanuts to the peanut oil press machine to squeeze out peanut oil. Pressing: In the process of peanut pretreatment and pressing, the oil residue in the peanut cake after pressing is about 7%. The peanut cake can be extracted by solvent to

The actual compression ratio of pressed material is 4-4.5, which is larger than soybean obviously, so the compression ratio should be 10 or so when using the screw oil press. The oil discharge gap of the press cage should be broadened and lengthened appropriately, and the inner diameter of pressing chamber should not be too large.