Large Scale Oil Press Machine - Peanut Oil Press Machine

- Type: peanut oil press

- Usage/Application: peanut, groundnut

- Production capacity: 500 TPD hydraulic press

- Voltage: 220V/380V/440V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): depends on capacity

- Country: lagos

The important difference between the oil press mode – with the cold press mode, the oil seed is fed to the machine without preheating while hot press method the oil seeds have to be preheated. Another important difference is the yield of oil and quality of the cake.

6YL-100 oil press - BTMA

- Type: peanut oil processing machine

- Production capacity: 98%-100%

- Voltage: 380

- Weight: 780kg

- Dimension (L*W*H): 2200*1600*2150

- Power (W): 5.5 KW~15KW

High Oil Yield Rate: compared with old and traditional oil press, the oil output rate of our oil press machine can be 5 to 8 percentage points higher. For example, use our oil press machine to process about 50 kg soybean can get about 3.5~4 kg crude soybean oil, which can greatly save cost and increase income.

If you are planning to buy groundnut oil processing machine, might as well first learn about the market of vegetable oil, oil extraction principles and oil production market. Buy from the groundnut oil machine manufacturers or suppliers with good after-sales and cost-effective price. Welcome to visit our factory for on-site inspection, or send us an inquiry online to enjoy one-one service on customized groundnut oil manufacturing business plan, equipment selection guide and cost details!

Peanut Oil Making Machines for Sale|Best Manufacturer

- Usage: peanut oil

- Production capacity: 23 kg/lot

- Voltage: 380 V

- Main components: motor, pressure vessel, pump, gear, bearing, motor, hydraulic box

- Weight: 2350KG

- Dimension (L*W*H): 1160*1200*1810 mm

As for small to medium peanut oil production machine, we suggest that you could consider the following model. 1. ZX-100 oil press, 3.5-5T/24hrs, FOB China port, with motor, export packing. 2. ZX-120 oil press, 5-7T/24hrs, FOB China port, with motor, export packing. 3. ZX-130 oil press, 10-12T/24hrs, FOB China port, with motor, export packing

Peanut oil pressing, also called mechanical pressing method, refers to the use of mechanical forces to squeeze oil out of peanut. The mechanical oil pressing method uses the power which is generated from the gradual reduction of the volume between the squeezed screw and the pressing chamber, as well as the power generated by the friction between the material and the machine to extrude the oil inside pretreated peanut.

Small Scale Oil Press Machine - Peanut Oil Press Machine

- Type: cooking oil extraction machine

- Production capacity: 1-2000TPH

- Power (W) : 18.5 KW

- Voltage: 220V/380V

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 1200kg

Edible oil press machine Edible oil press machine, which is also called oil expeller, oil extraction machine or oil mill. Suitable Seeds: Peanut, Soybean, Rapeseed, Sesame, Sunflower seeds, Walnut, Almonds, Pumpkin seeds, Corn germ, Cashew, Camellia seeds, Tea seed, Palm, Pepper seeds, Chili seeds, Til seeds, and also Jatropha seeds, Castor seeds,Cottonseed and Tung seeds for biodiesel.

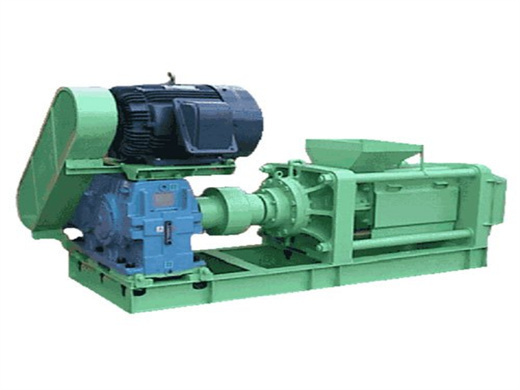

Groundnut Oil Press Peanut Oil Extraction Plant Twin Screw Oil Expeller Machine Cold Oil Press Machine 4-6T/D Cold Press: 4-6.5% (Rapeseed) 18.5+5.5Kw+80w :

6YL-68 Oil Press Machine: Efficient Oil Extraction for

- Raw Material: peanut

- Production capacity: 30T-300T/D

- Power (W): According to its capacity

- Voltage:220V/380V

- Dimension (L*W) *H): According to its capacity

- Weight: According to its capacity

The oil press machine is a versatile and efficient tool designed for extracting oil from various oilseeds. With its advanced technology and robust construction, it is widely used in small to medium-sized oil processing plants and households. This oil press machine offers a reliable and cost-effective solution for producing high-quality oil. Ⅲ.

Peanuts occupy a large proportion of the edible oil market. The pressing process is a traditional and common peanut oil processing method, but it cannot fully extract the oil, leaving a relatively high residual oil in the cake. This has little impact on small and medium-sized oil mills, but for large edible oil processing plants, it is crucial to fully utilize oil resources to reduce production costs and increase profits, allowing the oil plant to stand firm in the fierce market competition.