15 kilograms white peanut oil press machine in zimbabwe

- Type: peanut oil press

- Usage/Application: peanut, groundnut

- Production capacity: 98%-100%

- Voltage: 220V/380V/440V

- Weight: 1200kg

- Dimension (L*W*H): 1700*1100*1600mm

- Power (W): 5.5 kW

- Country: zimbabwe

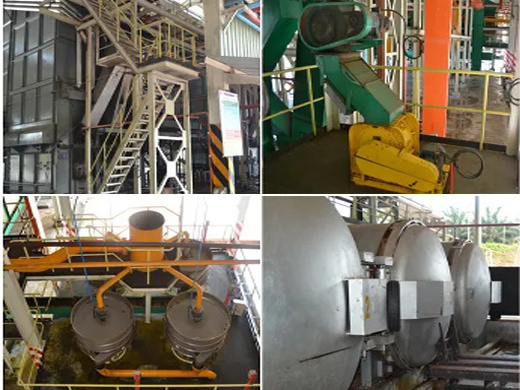

In the production process of groundnut oil processing plant, oil refining processes are particularly important. Peanut oil refining equipment is a device that can process many impurities in crude oil. The presence of impurities in the crude oil not only affects the edible value and safe storage of oil, but also brings difficulties to deep processing. Using peanut oil refining equipment for oil refining, it will not remove all the impurities in crude oil, but rather removes the impurities contained therein that are harmful to food, storage, and human health. For example: protein, phospholipid, moisture, etc.

Peanut Oil Press-- Integrated Screw Oil Press for Both Cold

- Type: peanut oil processing machine

- Production capacity: 80-800kg/h-99%

- Voltage: 380V

- Core Components: Motor oil

- Weight: 1900 KG

- Dimension (L*W*H): 2650*1900*2700 mm

Automatic peanut oil press machine is a kind of superior oil pressing machine nowadays in the market. It is used for processing cooking oil from various oil bearing materials such as peanuts, soybeans, sunflower seeds, rapeseeds, oil palm, sesame seeds and so on. This peanut oil extraction machine is an integrated oil press machine and suitable

As for small to medium peanut oil production machine, we suggest that you could consider the following model. 1. ZX-100 oil press, 3.5-5T/24hrs, FOB China port, with motor, export packing. 2. ZX-120 oil press, 5-7T/24hrs, FOB China port, with motor, export packing. 3. ZX-130 oil press, 10-12T/24hrs, FOB China port, with motor, export packing

Buy Ideal Peanut Oil Making Machine at Wholesale Price

- Usage: peanut oil

- Production capacity: 1-50T/D

- Voltage: 380V/440v

- Weight: depends on capacity

- Dimension (L *W*H): depends on capacity

- Power ( W): 20-50KW

Generally, a small scale groundnut oil processing plant ranges from 1tpd to 30tpd. To produce high quality edible oil, it is highly recommended to have all the necessary groundnut oil processing machines, including seed cleaning machine, peanut sheller, cooker, oil press machine, oil filter, or oil refinery machine.

Oil Press Machine, 1800W 110V Electric Oil Extractor Commercial Stainless Steel Oil Press Machine Nut Seeds Oil Extractor Cold& Hot Press Machine, Temperature Control 300°C/572°F,Lower Noise Price, product page $268.00 $ 268 . 00

Manufacturer & Supplier of Efficient Peanut Oil Press

- Type: cooking oil extraction machine

- Production capacity: 250-300 KG/H

- Voltage: 380V

- Weight: 2200 kg

- Dimension (L*W*H): 2000x1200x2500mm

- Power (W ): 3KW

Our products range from small peanut oil presses to large industrial peanut oil production lines to meet the needs of customers of different sizes. The main equipment includes peanut pretreatment equipment (cleaning machine, shelling machine, flaking machine, etc.), peanut oil presses, peanut oil refining equipment and related auxiliary equipment.

Use the electric motor or diesel as engine; high oil output,qualified oil,simple design and continuous operation;pressing various oil seeds,such as peanut, soybean,flax seed,cotton seed and so on;labor and energy saving because of the improved design;

peanut oil press machine for sale/large peanut oil processing

- Raw Material: peanut

- Production capacity: 150-300 kg/h

- Dimension (L*W*H): 1900* 1400*1700mm

- Voltage: 220v/380v/Customer request

- Weight: 1100 KG

- Main components: Motor

The peanut oil press machine is equipped with a vacuum oil filter, which can ensure the filtering while squeezing the oil, greatly improving the efficiency of the oil squeezing. The oil press machine has a variety of models, and customers can choose the machine according to their own output requirements.

High Efficiency: Employing advanced oil pressure technology, our machine guarantees an extraction rate of up to 90%, maximizing your investment returns and productivity. 2. Fully Automated Operation: The fully automated control system streamlines your processes, significantly reducing labor costs while enhancing overall production efficiency.