Peanut Oil Processing Technology - ScienceDirect

- Type: peanut oil press

- Usage/Application: peanut, groundnut

- Function: Filter seed oil

- Production time: in stock

- Shipping: by fast shipping

- Payment: Tt

- Package: Wooden box

- Country: lagos

The conditioned peanut kernels are transported by a conveyor to the twin-screw press for cold pressing; the cold-pressed crude oil and cold-pressed peanut meal with low denaturation will be obtained. After the cold-pressed crude oil is filtered with frame filter, product oil is obtained, which will be packaged by a filling machine to form cold

Mechanical Methods of Oil Extraction from Peanuts

- Type: peanut oil processing machine

- Material: stainless steel

- Features: cold and hot pressed

- Keep Working: more than 8 hours

- Main components: motor

- Type of oil: cooking oil, tea View

In 2020, Shin et al. extracted oil from peanuts using the cold pressing method and aimed to valorize the partially defatted peanut meal (PDPM) obtained . In the process of producing cold-pressed peanut oil, mechanical shelling is commonly used, and the peanut kernels with red skin are then dehydrated to a moisture content of 4–8% to make them

Cold pressed peanut meal, also known as defatted peanut meal or pressed peanut meal, is a by-product of peanut oil extraction. It contains a high protein level (> 25%), and is white to creamy in color due to the mild thermal (< 60°C) treatment (Zheng et al., 2013).

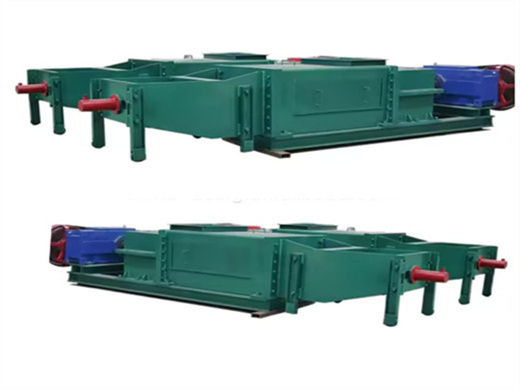

Peanut/Groundnuts Oil Processing | Hot & Cold Press

- Usage: peanut oil

- Production capacity: 45 sets per year

- Voltage: 380V/440V

- Weight: 500TON

- Dimension (L*W*H): 1200*2800*1200mm

- Power (W): 30KW

During this process, the cellular structure of the peanut is disrupted, making it easier for the oil to be released. The hot pressing method yields higher oil yields because the heat helps release the oil. Cold pressing: Peanuts are pressed at a lower temperature (60°C) without being steamed or fried during processing. This method aims to

Process of cold pressed peanut oil. Cold-pressed peanut oil is made by mechanically pressing peanuts at low temperatures without the use of chemicals or solvents. Here are the basic steps involved in the process: 1, Cleaning and sorting: The peanuts are first cleaned to remove any impurities, and then sorted to remove any damaged or diseased nuts.

Peanut Oil Processing Technology - ResearchGate

- Type: cooking oil extraction machine

- Voltage: 380 V

- Press Materials: Palm, All Palm

- Appearance: Vertical

- Press Series: Second

- Customized: Customized

In book: Peanuts: Processing Technology and Product Development (pp.63-81) Authors: Q. Wang. Q. Wang. Cold pressed peanut oil is composed mostly of unsaturated fatty acids, predominantly oleic

Secondly, the whole process realized the low temperature press, in the process, the high temperature value is less than 80°C, under this condition. high quality peanut oil can be obtained. Thirdly, the protein content of 50 to 60% high quality crude protein powder can be obtained after the cold pressed peanut cake is crushed, which lays the

Boost yield in peanut oil with optimal processing

- Raw Material: peanut

- Production capacity: 10TPD

- Dimension (L*W*H): depending on capacity<br /Weight: KG

- Voltage: 115V/220V/380v/440v

- Main components: motor, pump, bearing, motor

- Oil type: cottonseed oil

While both methods are part of the peanut oil production line, they have different outcomes. Mechanical pressing involves the mechanical screw, screw shaft, and the embryo slice to extract oil. The result is cold-pressed peanut oil, lauded for its high content of phospholipids, antioxidant vitamins, and amino acids.

Peanut Oil Press Solution. Including various peanut processing solutions,such as Automatic hydraulic oil press peanut paste press processing,Hydraulic oil press 100% cold press peanut processing, Screw oil press peanut processing etc. Get Started Now