Peanut Oil Production Line

- Type: peanut oil machine

- Usage/Application: peanut, groundnut

- Production capacity: 150-1000 kg/h

- Voltage: 240 V and 380 V

- Weight: 2.2 tons

- Dimension (L*W*H): 1500mm*2600mm*3600mm

- Power (W): 15 kW

- Country: zimbabwe

Stir the oil slowly to cool it to a certain temperature, and then pump the cooled oil into the oil filter for coarse filteration. Cooling and fine filtration process: pump the coarse filtered oil into cooling oil tank to further cool it to a lower temperature, and colloid impurities in crude oil temperatures condense gradually in the critical

Groundnut Oil Mill Plant - Oil Expeller

- Type: peanut oil processing machine

- Production capacity: 50-1000 t/d depends on your request

- Voltage: 380 V

- Weight: according to size

- Dimension (L*W*H): according to your request

- Power (W): as capacity

The Groundnut / Peanut Oil Production Line offered by GOYUM is robust, versatile, reliable and efficient. This Groundnut / Peanut Oil Production Plant is based on practically proven technology which is not only energy efficient & environment friendly, but also economical.

This is a small scale edible oil production line that connects the basic peanut oil making machines. It is mainly equipped with conveyor, sheller, cooker, oil press and oil filter machine. For many starters who are planning to involve in peanut oil making business, this is a BEST choice due to its low cost, high oil output and easy operation.

10TPD Complete Peanut Production Line Established in zimbabwe

- Usage: peanut oil

- Production capacity: 5TPD-100TPD

- Voltage: 380V or 440V

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox

- Weight: 20000 KG

- Dimension (L*W*H): 1200*1600*1350mm

In January 2022, we received an inquiry from a Chad customer about a peanut production line. During the communication process, the customer originally wanted a production line with a processing capacity of 10ton, working 16 hours a day, and finally obtaining 5 ton of refined oil.

Pre-press process introduction: 1.Flow chart: Peanut seed→Metering→Cleaning→Crushing→Cooking→Flaking→Pre-press→Pressed cake to packing line ↓ Crude oil filter→to the refining plant 2. Process characteristic: 1) Full continuous and mechanized operation, and with electrical interlocking control system. 2) The equipment layout is in tower structure, and the material flow by

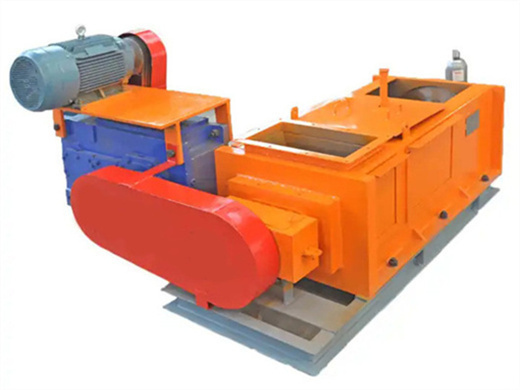

Peanut oil press production line - Oil press machine

- Type: cooking oil extraction machine

- Production capacity: 10T-3000T/D

- Power (W): According to the request of the canola oil refining machine

- Voltage: 380V

- Dimension (L*W*H) ): According to the request of the canola oil refining machine

- Weight: According to the request of the canola oil refining machine

The groundnut oil squeezed by an automated peanut oil processing machine is clean, free of impurities, and of good quality. The peanut oil pressing line mainly includes a peanut shelling machine, roasting machine, oil press, vacuum oil filter, and oil filling machine. The peanut oil pressing process mainly includes hot pressing and cold pressing.

Main Machines in Edible Oil Production Line 1. Oil seed Shelling Machine Some oil seeds have shells which have to be removed before pressing. Our peanut shelling machine can shell the peanuts by rubbing force, separate the shells and kernels by wind force and then separate the unshelled peanuts by gravity separating screen. The unshelled

Fully Automatic Groundnut/Peanut Oil Production Line

- Raw Material: peanut

- Production capacity: 5t/day-5t/hour

- Dimension (L*W*H): 3806*1238*3418

- Voltage: 380V

- Weight: 8500 KG

- Main components: Motor, bearing, motor, gearbox

Peanut Oil Production Line. Peanut is a kind of oilseed with high oil content. The oil can be obtained from peanuts by pressing process. Groundnut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid). Besides, there are also palmitic acid, stearic acid, and other saturated fatty acids which

The peanut oil production line is a production line composed of sheller, Conveyor,Roasting Machine, oil press, and Oil Filter Machine.The peanuts are cleaned and put into the peanut sheller to remove their shells. The Conveyor transports the materials to the Roasting for frying, and then sends them to the oil press for squeezing.