used vegetable peanut oil processing machines soy in ghana

- Type: peanut oil refinery machine

- Usage/Application: peanut, groundnut

- Production capacity: 400kg

- Voltage: 380V-50hz

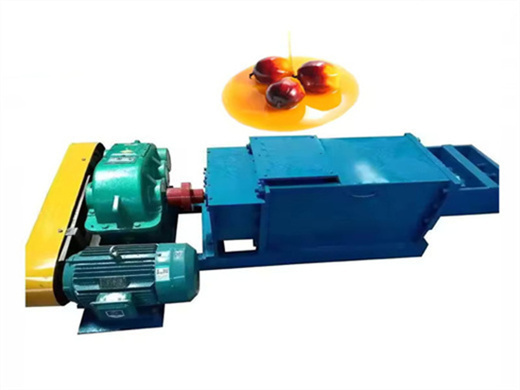

- Oil type: Palm oil,attrValueId: 13238208

- Main components: Gearbox, Pressure vessel, Pump, Gear, Bearing, Motor, PLC, Others

- Dimension (L*W*H): 210*140*170cm<br / / Weight: 1300 KG

- Country: ghana

Application: crude Peanut oil processing plant; Function: Chemical oil refining and physical oil refining; Application range: 10-1000tpd; Advantage: Low consumption; Power consumption: 17.5kwh-24kwh; Steam consumption: 200-300kg per one ton crude oil; Exporting Countries: ghana; Salad and cooking oils or frying fats can be made almost solely

Peanut Oil Making Machines for Sale|Best Manufacturer

- Type: peanut oil refinery machine

- Production capacity: 10T-3000T/D

- Voltage: 220V/380V

- Weight: According to the capacity of soybean oil production machine

- Dimension (L*W* H): According to the capacity of the soybean oil production machine

- Power (W): Capacity

The oil content of peanut is approximately 42% to 52% oil. Peanut oil is mainly used for cooking purpose as it contains lots of protein and 80% unsaturated fatty acids like oleic acids and linoleic acids. Peanut oil is in light yellow transparent color and has a fragrant smell, and their taste is very delicious. Groundnut / Peanut Oil Making

Is small- scale groundnut oil processing a profitable business? How about the costs and returns? When running groundnut oil plant, the key is to minimize the capital and operating coast, and maximize the incomes from the sales of oil and other co-products. So it is necessary to do a careful study of all costs before setting up your own oil processing plant. In particular to assess the cost of purchasing the main peces of equipment, expected labor wages and oilseeds purchase cost, the cost of fuel and power. The price of produced oil and co-product depends on many factors including, quality, the number of competitors, and their type and oil quality.

Oils Fats Refining Equipment and Turnkey Plants - Myande Group

- Usage: peanut oil

- Production capacity: as per cooking oil press machine specifications

- Voltage: 220V/380V

- Weight: according to the specifications of the cooking oil presser machine

- Dimension (L*W*H): according to the specifications of the machine cooking oil presser

- Power (W): according to the specifications of the cooking oil press machine

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Peanut oil pressing, also called mechanical pressing method, refers to the use of mechanical forces to squeeze oil out of peanut. The mechanical oil pressing method uses the power which is generated from the gradual reduction of the volume between the squeezed screw and the pressing chamber, as well as the power generated by the friction between the material and the machine to extrude the oil inside pretreated peanut.

Hongde Provides Turnkey Oil Mill Plant, Oil Pressing Machine

- Type: cooking oil refining machine

- Voltage: 230-380-430

- Dimension (L*W*H): 20m*16m*15m

- Power (W): 40kw/h

- Weight: 30 tons

- Certification: CE and ISO9001

Cotton Seed Oil Refinery Plant. Oil Refining is the progress of removing impurities such as phospholipids, FFA, pigment, and off-flavor in cruel oil before edible application. An oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining

Discover high-efficiency edible oil refinery machines designed for optimal oil purification and processing. Suitable for various oils like soybean, sunflower, palm, and peanut, these machines ensure premium quality oil with advanced refining technology. Enhance your production with our durable and cost-effective solutions.

Manufacturer & Supplier of Efficient Peanut Oil Press

- Raw Material: peanut

- Residual oil in flour: less than 1%

- Energy consumption: no more than 15 KWh /T

- Solvent consumption : less than 2 kg/t

- Moisture of finished food: ≤ 13% (adjustable)

- Crude oil moisture and volatile matter: ≤ 0.30%

Our main products include small oil presses, medium-sized commercial oil presses, large peanut oil production lines, vegetable oil refining plants, other seed oil extraction equipment, etc., which can meet the needs of different customers. In addition, we also provide a full set of oil extraction, refining and packaging solutions.

What parts are included in a peanut oil screw press? Peanut oil screw press mainly consists of five parts: hopper, gear box, press chamber, press screw and frame. Among them, the press screw is the key of the whole peanut oil screw press, and the choice of its material will affect the quality and service life of the press. 2024-08-26