Peanut Oil Production Plant Investment Costs Analysis

- Type: peanut oil refinery plant

- Usage/Application: peanut, groundnut

- Production capacity: 2T~10T/D

- Voltage: 220V/380V

- Weight: 2000kg

- Dimension (L*W*H): 20*15*7m

- Power ( W): according to capacity

- Country: uganda

The general capacity we can provide for peanut oil processing plant ranges from 5 to 400 tons per day. Taking the smallest peanut oil production line (5TPD) as example, the totally investment for a complete automatic peanut oil production line is $ 8,500 around (Not include the oil refining equipment). Please note all the equipment included

What is the cost of setting up an edible oil refinery plant

- Type: peanut oil refinery machine

- After-sales service: Online video

- Warranty: 1 year

- Voltage: 380V

- Press series: Third

- Structure: Vertical

1, Edible oil refinery plant construction cost. The price level of each country and each region is different, which is mainly based on the actual situation in the local area; 2, edible oil refinery plant cost. Different edible oil refining technologgy, different capacity edible oil refinery plant, the prices is different.

Of course, how much does the peanut oil refining equipment production line cost? The price of full continuous equipment is higher than that of semi-continuous equipment and batch equipment! Take the peanut oil refining equipment with a daily output of 1 ton as an example.

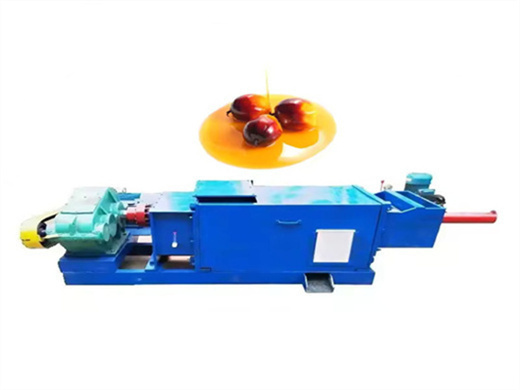

Groundnut Oil Making Process (Peanut), Business Plan

- Usage: peanut oil

- Production capacity: 1TPD-1000TPD

- Voltage: 220V/380V

- Weight: 600kg -1600kg

- Dimension (L*W*H): 1700*1100*1600mm

- Power (W) : 5.5 kw- 15kw

Today, let us discuss the groundnut oil production process, extraction methods, and business plant including groundnut oil plant (machine) cost in India. Groundnut oil is also known as peanut oil or Arachis oil, is a mild-tasting vegetable oil expressed from groundnut kernels. Groundnut oil is generally used in cooking, including frying

Some oil with national or industrial standards, a complete edible oil processing plant can reach the corresponding standards through oil refining. If there is no standard, we suggest to have edible oil refining process, In this way, higher quality edible oil can be produced. (Related Post: Cost of Building a Palm Oil Refinery >>)

Small Edible Oil Refinery Plant

- Type: cooking oil refining machine

- Machine type: HIGH PRESSURE WASHER

- Feature: Non-toxic

- Cleaning type: Clean -In Place (CIP)

- Cleaning process: Cold water cleaning

- Fuel: Diesel

Equipment Included in The Small Edible Oil Refinery Plant. Edible Oil Refining Process . Heat Conduction Oil Furnace: 1 set (Produce enough heat for the refining sections, temperature≥240℃) Steam Generator: 1 set (Produce steam for the deodorization process) Refining Pot: 2sets (Remove the gum, phosphoric acid etc.)

In general, there're 3 types of peanut oil refinery plant, batch type, semi-continuous and full-continuous. 1-2-3-5-10TPD batch type peanut oil refinery plant. 10-15-20-25-30-50TPD semi-continuous peanut oil refinery plant. 50-80-100-150-300-600-2000TPD full-continuous peanut oil refinery plant. Different capacity peanut oil refinery machine

How much does it cost to build an oil refinery and how long

- Raw Material: peanut

- Production capacity: 10T-3000T/D

- Power (W): 10-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W* H): 1610x615x1260mm

- Weight: 1050 KG

Generally, the higher the refining capacity, the higher the overall cost. Henan Glory's product range includes a wide range of edible oil refineries, which can be divided 1-20tpd batch type edible oil refining machine, 10-50tpd semi-continuous edible oil refinery plant and 30-1000tpd full-continuous edible oil refinery plant by type.

Starting an edible oil refinery for commercial purposes is popular in south africaia, Moldavia, Brazzaville, Jamaica, Ghana, Tanzania, malawi and many other countries. Whether you know about edible oil production or not, basic cooking oil production process, a complete edible oil refining line is extremely important for an edible oil refinery and even a key factor in the success or failure of an