The Definitive Guide to Peanut Oil Refining Process

- Type: peanut oil refining mill

- Usage/Application: peanut, groundnut

- Production capacity: 5TPD

- Voltage: 220V

- Warranty: 1 year, One year

- Weight: 6400 KG

- Dimension (L*W*H): 3340x2100x2160

- Country: johannesburg

The peanut oil refining process is to transform crude peanut oil into a high-quality edible oil. Include degumming, deacidification, decolorization, and deodorization. info15@cnoilmachine.com 0086-159-3728-9608 0086-159-3728-9608

Edible Oil Mill Plant Supplier. Edible Oil Press Machines

- Type: peanut oil refinery machine

- Production capacity: 1-2000TPD

- Voltage: 380V/50HZ

- Weight: 1200kg

- Dimension (L*W*H): 1700*1100* 1600mm

- Power (W): 15KW

30TPD – 1,200TPD Rapeseed oil refining plant; 30TPD – 1,200TPD Peanut oil refining plant; 30TPD – 1,200TPD Cottonseed oil refining plant; 30TPD – 1,200TPD Sunflower oil refining plant; 30TPD – 1,200TPD Corn germ oil refining plant; 30TPD – 1,200TPD Castor seed oil refining plant

Established in 1990, Henan Kingman Mechanical & Electrical Complete Plant Co., Ltd. (KMEC) deals principally in designing, manufacturing and exporting complete oil mill plants, solvent extraction plants and related oil processing equipment. We also provide professional customized edible oil refining and a variety of oilseed processing services.

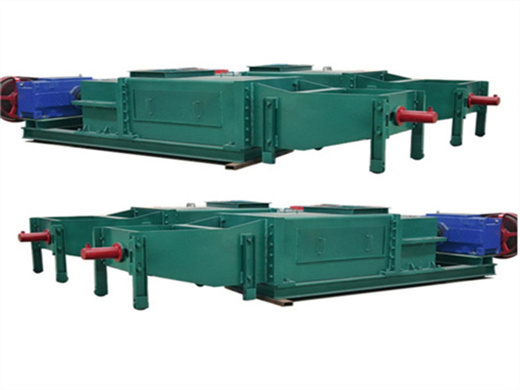

Batch Type Small Edible Oil Refining Plant - Oil mill

- Usage: peanut oil

- Processed raw material: grass, rice husk, wood sawdust, biomass, straw, cotton stalks

- Pellet diameter (mm): 6 - 12

- Dimension (L*W*H): 1000*450*850

- Voltage: 380v/50hz

- Production (kg/h): 100 - 12000 kg/h

The Batch-type edible oil refining equipment is designed to handle various types of crude oils, including palm oil, soybean oil, sunflower oil, peanut oil, and more. It performs several refining processes in a batch mode, allowing for flexibility and control over the refining process.

We are able to supply the professional oil refining plant and related oil refining equipment. With a high degree of automation, the oil refining machinery can refine 20 kinds of oil, such as soybean, rape seeds, peanut, etc. in a small production line or in a large oil plant. SEE MORE

Complete Facility of Peanut Oil Processing Mill | Edible Oil

- Type: cooking oil refining machine

- Production capacity: 50-3000TPD

- Power (W): As cold press machines produce every day

- Voltage: 380v 440v

- Dimension (L*W*H) ): According to the daily production of your cold press machines

- Weight: depends on the production of cold pressing machines

Peanut oil processing mainly involves several processes, including peanuts shelling, peanuts pretreatment, peanuts oil extracting, peanut oil filtering and peanut oil refining. Surely, for different scale of the peanut oil processing factory, the equipment are decided by the specific process. An Example of Mini Peanut Oil Mill (1~10T/D)

The degumming process in an oil refining plant is to remove gum impurities in crude oil by physical or chemical methods, and it is an oil purification process. In the edible oil refining process, the most commonly used method is hydrated degumming, which can extract the hydratable phospholipids and some non-hydrate phospholipids, the remaining

Professional Oil Refining Plant for Edible / Vegetable Oil

- Raw Material: peanut

- Production capacity: 20~2000T/D

- Power ( W): 7.5kw

- Voltage: 380v/50Hz

- Dimension (L*W*H) : 2050*1350*2000Weight: 1000kg

- Function: oil production/manufacturing machine line

Less bleaching earth necessary compared with physical refining; Oil Refining Process. With 10 years' experience in manufacturing and exporting complete oil mills as well as a variety of oil mill machinery, KMEC is an expert in edible oil refining. In the oil refining plant, there are several steps to follow.

After this step, these crushed seeds are pressed by oil expellers to squeeze out the peanut oil from them. This EXTRacted oil has many impurities and has to be cleaned and this is the step which takes a long time. The crude oil is sent to the oil refinery plant where the oil is sent for the further processing.