30T/D Peanut Oil Mill Plant In Sudan

- Type: peanut oil refining mill

- Usage/Application: peanut, groundnut

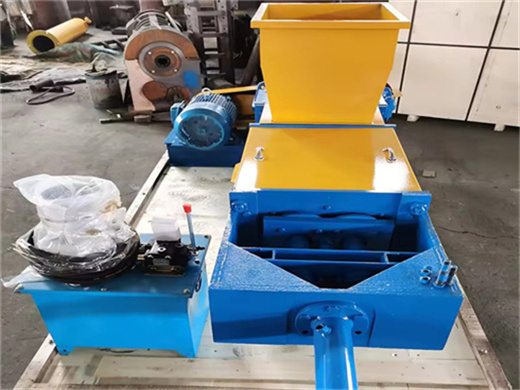

- Machine Type: Granulator

- Product Type: Fertilizer

- Weight: 2-70t

- Dimension (L*W*H): Depending on the model

- Power (W): 37- 90kw

- Country: lagos

In the production process of groundnut oil processing plant, oil refining processes are particularly important. Peanut oil refining equipment is a device that can process many impurities in crude oil. The presence of impurities in the crude oil not only affects the edible value and safe storage of oil, but also brings difficulties to deep processing. Using peanut oil refining equipment for oil refining, it will not remove all the impurities in crude oil, but rather removes the impurities contained therein that are harmful to food, storage, and human health. For example: protein, phospholipid, moisture, etc.

turenkey peanut oil refining equipment in sudan | oil

- Type: peanut oil refinery machine

- Production capacity: STANDARD

- Voltage: 380V

- Dimension (L*W*H): STANDARD

- Weight: STANDARD

- Power (W): STANDARD

This is the peanut oil extraction process. The configuration of the peanut oil production line needs to consider various factors such as the size of the investor's plant, production capacity, quality, and budget. Equipment configuration plans and quotations are provided as needed. The manufacturer has been focusing on the research and production of oil machinery for many years, producing high-quality equipment with a complete range of types and models, offering customized services and production line configurations as needed.

30T/D Peanut Oil Pressing and 15T/D Peanut Oil Refinery Project in Sudan 30T/D Peanut Oil Press Machine Processing Line in Sudan 2015 Henan Hongde Singed 50TPD Peanut pretreatment and 15TPD Peanut Oil Refining Equipment With south africaia Customer

Hongde Provides Turnkey Oil Mill Plant, Oil Pressing Machine

- Usage: peanut oil

- Production capacity: 10T-3000T/D

- Voltage: 380V

- Weight: 2 TONS

- Dimension (L*W*H): 1700*1100*1600mm

- Power (W ): 11KW

30T/D Peanut Oil Pressing and 15T/D Peanut Oil Refinery Project in Sudan. READ MORE. Ethiopia 30T Sesame Oil Mill Machine Start Production.

30T/D Peanut Oil Pressing and 15T/D Peanut Oil Refinery Project in Sudan info@Hongdeoilmachine.com 0086-0371 Ethiopia 30T Sesame Oil Mill Machine Start Production.

15TPD Peanut Oil Hot Pressing Machine for Sudan Market

- Type: cooking oil refining machine

- Production capacity: 15-20 kg/h

- Voltage: 220/110 V

- Main components: motor

- Weight: 50 kg

- Dimension (L*W*H): 600*306*775 mm

15TPD Peanut Oil Hot Pressing Machine for Sudan Market. No reviews yet. Henan Hongde Cereals And Oils Machinery Co., Ltd. Custom manufacturer 15 yrs CN .

30T/D Peanut Oil Mill Plant in SudanHenan Hongde has make successful design, manufacture and installation of 30T/D Peanut oil mill plant in Sudan. machine peanut oil production line GET PRICE 30T/D Complete Peanut Oil Mill Plant Launched In Sudan

Customization Peanut Oil Refinery Mill Machine in Sudan

- Raw Material: peanut

- Production capacity: 10--500T/D

- Dimension (L*W*H): 2000x1400x1850mm

- Voltage: 220/380V

- Weight: 1100 KG

- Main components warranty: 5 years

Peanut oil, also known as groundnut oil, can be extracted by pressing, pre-pressing and solvent extraction, etc. Among them, the most widely used extraction method is pressing. The processing of peanut oil is mainly based on hot pressing, because the hot pressing process can get rich peanut flavor and keep the nutritional components and physiological active components in peanut to the maximum extent. Next, we will introduce the production process of extracting peanut oil by pressing technology. (Please click here for the technology of extracting peanut oil by solvent extraction)

Peanuts occupy a large proportion of the edible oil market. The pressing process is a traditional and common peanut oil processing method, but it cannot fully extract the oil, leaving a relatively high residual oil in the cake. This has little impact on small and medium-sized oil mills, but for large edible oil processing plants, it is crucial to fully utilize oil resources to reduce production costs and increase profits, allowing the oil plant to stand firm in the fierce market competition.