Peanut proteins: Extraction, modifications, and applications

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 3.5-5.50kg/h

- Voltage: 220v/110v, 60Hz/50Hz

- Main components: Motor

- Weight: 12 KG

- Dimension (L*W*H): 45* 18*30.5 cm

- Country: zimbabwe

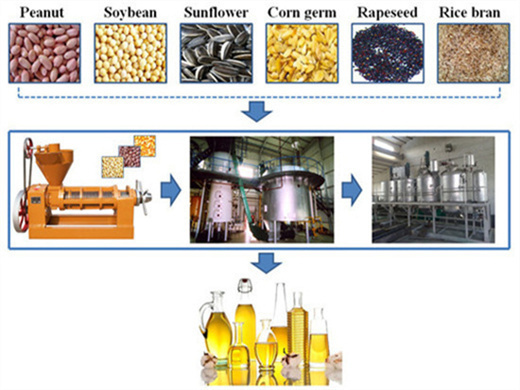

Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent (n-hexane) extraction [29]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

Mechanical Methods of Oil Extraction from Peanuts

- Type: peanut oil processing machine

- Production capacity: 15-20 kg/h, 100%

- Dimension (L*W*H): 700x700x940mm

- Oil type: Cooking oil

- Main components: Motor

- Weight: 126 KG

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

Peanut oil is extracted by employing hydraulic presses and expellers, and the method of solvent extraction. Peanut oil is rich in oleic, palmitic, and linoleic acids and possesses good oxidative stability. Aflatoxins, often present in raw contaminated peanuts, should preferably be absent in refined oil or within the legally permitted level.

A comprehensive insight into peanut: Chemical structure of

- Usage: peanut oil

- Production capacity: 1TPD-1000TPD

- Voltage: 380V

- Weight: changed with capacity

- Dimension (L*W*H): various with capacity

- Power (W): according to capacity

The oil extraction using cold-pressing method is performed at temperatures below 60 °C while in a hot-pressing condition, high temperatures are applied (Tan et al., 2020). Although peanut oil produced by hot-press is more popular due to its better aroma and flavor, it may lose its micronutrient due to proton denaturation at high temperatures.

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

What is the basic principle of peanut oil solvent extraction?

- Type: cooking oil extraction machine

- Voltage: 380V

- Dimension (length x width x height): 1910*550*765 mm

- Power: 2.2 KW

- Weight: Based on the capacity of the oil puffing pressing plant

- Certification: CE,ISO9001

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

processing most widely used is the peanut oil. The peanut cake or meal obtained after oil extraction which can be full fatted, partially defatted or defatted is later used as flour, isolates and concentrates [6]. Oil extraction from the peanut kernel is a well-established industrial since the early 1950s. They have thus supported in

Bioactive Phytochemicals from Peanut Oil Processing By

- Raw Material: peanut

- Production capacity: 10T-5000TPD

- Power (W ): 10kw-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2500mm*2000mm*3000mm

- Weight: 2T-20T

The peanut-defatted peanut meal is a biowaste derived from oil extraction. It is white creamy in color and has a high protein level (>25%) [ 15 ]. In addition, peanut lectin, resveratrol, and piceid are bioactive compounds available in the defatted peanut meal [ 5 ].

Recommended reading: Peanut oil processing plant. Peanut oil pretreatment and pressing machine. Although the peanut pretreatment machine is necessary, the peanut oil press machine is also important. As the core equipment of the peanut oil pressing production line, peanut oil press machine plays a huge role in the whole peanut oil pressing process.