Oil press - Screw oil press is an efficient,... | Facebook

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- Production capacity: more than 95%

- Voltage: 220V/110V

- Control mode:: cooking oil making machine

- Oil product: oil making machine

- Dimension (L x W x H): 45 x 21.5 x 24 cm Weight: 12 kg Main components: Gearbox, Motor, PLC

- Country: indonesia

Screw oil press is an efficient, environmentally friendly and intelligent oil extraction equipment, adopting directional pressure and multi-stage propulsion technology, which can complete the...

Steps of Peanut Oil Production Line - Oil Processing

- Type: peanut oil processing machine

- Voltage: 380 V

- Power (W): Standard

- Certification: CE,ISO

- Weight: standard

- Dimension (L*W*H): standard

The cooking process influences directly on the smooth press, oil rate and oil cake quality. When the moisture content is close to 1-2% and the temperature reaches 120-130℃, peanut is suitable to finish cooking and begin to press. Pressing Here we adopt screwOil Pressing Machine which is widely used in small sized oil plant. Simple operation

GOYUM SCREW PRESS is a leading manufacturer of groundnut / peanut / earthnut oil mill plants. We have exported oil mill machinery and equipment for customers around the world. Our groundnut oil extraction machines are successfully running in India, south africaia, Tanzania, Chad, malawi, Cameroon, Ethiopia, south africa, Ghana, Sudan, indonesia, lusaka

Twin Screw Oil Press Machine Cold Oil Expeller - Peanut Oil

- Usage: peanut oil

- Production capacity: 50-800 kg/h

- Voltage: 115 V/220 V

- Main components: others, gears, bearings

- Weight: 12 KG

- Dimension (L*W) *H): 380*160 *345mm

Cold pressing cake temperature is lower than 70℃ which assures good quality of oil and cake.Twin-screw expeller is suitable for pressing de-hulled oilseeds with obvious quality improvement of oilseeds oil and reduction of energy consumption, which can increase processing value of double-low oilseeds.

Different processing sections and the related oil processing equipment need to be taken into consideration in peanut oil processing. Steps such as seed preparation, oil pressing, oil extraction, and oil refinement must be expertly enjoined to produce the highest quality oil. Peanut oil contains high amounts of energy and fat-soluble vitamins (A, D, E, and K) and essential fatty acids. The oil content of the kernels is between 45% and 55%.

peanut oil press machine for sale/large peanut oil processing

- Type: cooking oil extraction machine

- Production capacity: 1tpd-1000tpd

- Dimension (L*W*H): 3750*850*1990MM

- Voltage: 220V/380V

- Weight: 880kg

- Warranty: 1 year, 12 Months

The peanut oil press adopts the row method to greatly reduce the gap of the oil line, increase the pressure of the press chamber, and increase the oil yield. The commercial screw peanut oil expeller machine uses electronic temperature control technology to ensure the best temperature for the oil output rate of the press chamber.

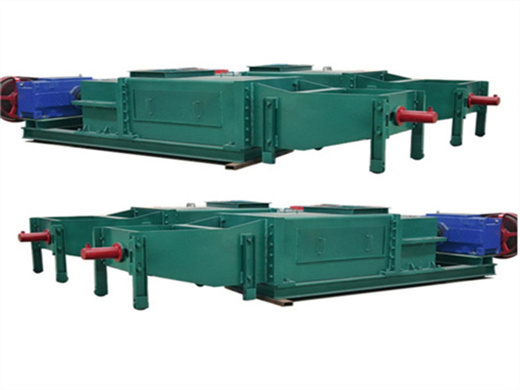

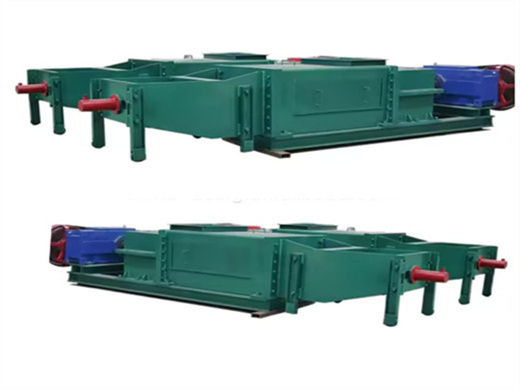

With the features of large processing capacity, low power consumption, low operating cost, loose cake structure without breaking, easy solvent penetration, low residual oil rate, etc., ZY32 type screw oil press is an ideal oil extraction equipment for large-scale oil plants.

Peanut Oil Production Line,Peanut Oil Pressing Plant

- Raw Material: peanut

- Production capacity: 100%

- Power (W): 11KW

- Voltage: 380V

- Dimension (L*W*H): 1200*400*900mm3

- Weight: various

Peanut oil (groundnut oil), as a kind of light yellow transparent edible oil with a pleasant fragrance and good taste, is relatively easy to digest. Peanut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid).

Peanuts occupy a large proportion of the edible oil market. The pressing process is a traditional and common peanut oil processing method, but it cannot fully extract the oil, leaving a relatively high residual oil in the cake. This has little impact on small and medium-sized oil mills, but for large edible oil processing plants, it is crucial to fully utilize oil resources to reduce production costs and increase profits, allowing the oil plant to stand firm in the fierce market competition.