Groundnut Oil Manufacturing Machine

- Type: peanut oil mill

- Usage/Application: peanut, groundnut

- Production capacity: over 98%

- Voltage: 220 V/110 V

- Warranty: 1 year

- Weight: 1600kg

- Dimension (length x width x height): 56 x 18 x 35 cm

- Country: indonesia

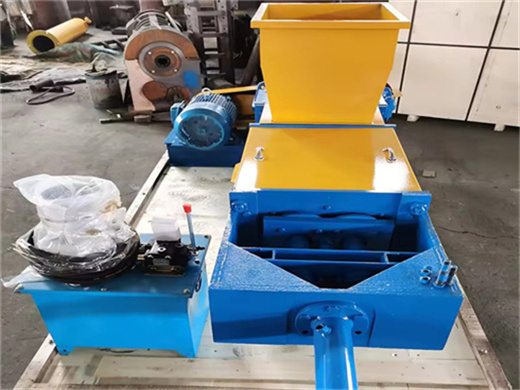

The dehulling process can be done manually by labor, or by use of dehuller to reduce the manpower and shorten production time. The purpose of dehulling before oil pressing is to reduce the absorption of oil by the shell, increase the yield of oil, improve the processing efficiency of the peanut oil processing machine and reduce equipment wear

Session 4.8 – Oil Extraction Technology

- Type: peanut oil processing machine

- Voltage: 380 V

- Appearance: Vertical

- Custom: Custom

- Press Series: Second

- Press Materials: Sunflower, All Seeds

The process is relatively simple and not capital-intensive. While the smallest solvent extraction plant would have a processing capacity of 100-200 tons per day, expellers are available for much smaller capacities, from a few tons per day and up. The main disadvantage of the screw-press process is its relatively low yield of oil recovery.

Peanut oil pressing methods. Divided by pressing temperature, there are two types of peanut oil pressing methods they are hot pressing technology and cold pressing technology. Hot pressing method is the traditional process of peanut oil. Peanut oil is steamed fried and pressed, generally at a temperature above 120 ℃ with a high rate of oil

Peanut oil processing ppt - edible oil extraction machine

- Usage: peanut oil

- Power Source: Electric

- Automatic Grade: Semi-Automatic

- Weight: 12000 kg

- Main material: SUS 304

- Size: Customized

If yes, you should look at the following passage carefully. Henan Doing Company is a professional world-wide cooking oil processing machine supplier. Next let us see the peanut oil processing ppt to learn the whole peanut oil processing process. Peanut oil processing machine. The whole peanut oil processing machine contains three workshops: 1.

These oil mill can process a number of oilseeds like peanut, soya, cotton seeds sunflower seeds, corn germ, rape seeds, canola, castor, sesame, neem seed, sheanut, palm kernel and the like. The most important equipment in the entire milling / pressing process is oil expellers which are used for high oil content seeds and also used for smaller

Groundnut Oil Mill Project Report - ilgusto-restaurant.de

- Type: cooking oil extraction machine

- Product type:Wood oil

- Packaging:Bulk

- Processing type:Refined

- Purity (%):100

- Volume (L):5

4. To build a project report, learn the production process, quality control needed for raw materials, financial elements such as projected sales 5. Peanut Oil Manufacturing Industry. Groundnut Oil Production 1. 01.PROJECT REPORT - Cold Processed Oil PDF Cost Of Goods Sold Peanuts 2.

Do you want to start peanut oil business? But you do not know where to start. We "Goyum Screw Press" help you start your oil plant. We have experience above four decades in the design and manufacturing of oil mill machines and equipment. This presentation can help you understand which equipment and machines are necessary in the peanut oil mill

Groundnut Oil Mill / Extraction Plant Manufacturer & Exporter

- Raw Material: peanut

- Production capacity: 80-150 kg/h

- Power (W): 5.5 kW

- Voltage: 380 V/50 HZ

- Dimension (L*W*H): 1700*1100*1600 mm

- Weight: 1200 kg

Groundnut Oil Mill Plant Process. Groundnuts are also known as Peanut or Earthnut. The oil content in the peanuts is between 35% and 45% depending on the variety. Groundnut oil extraction involves several processes including groundnut decortication, cleaning, seed conditioning, crushing and filtration.

Peanut oil in choline, but also improve the memory of human brain and slow decline of brain function. Process: Peanut raw materials – Screening- Broken –steam cooking for embryos-filter press-crude peanut oil-oil refining-refined peanut oil. The methods for peanut oil refinery includes chemical oil refinery and physical oil refinery.