Facilities & Capabilities | John B. Sanfilippo & Son, Inc.

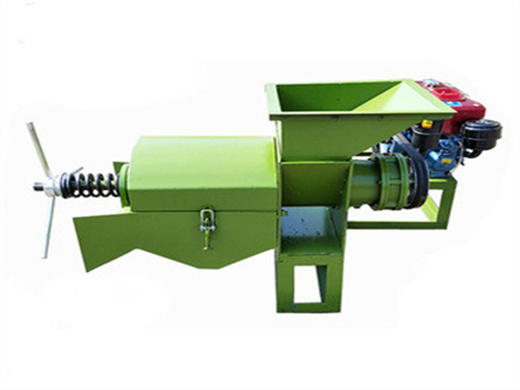

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 1t/day-1t/hour

- Voltage: 380v/50hz; 420v/60hz

- Oil type: cooking oil

- Main components: motor, pump, motor, gearbox, others

- Weight: 30000 KG

- Country: rwanda

The only fully integrated peanut processing facility in the U.S. is a sprawling 245,000 square feet. Over 120 million pounds of runner type peanuts are shelled and processed annually. Shelling, blanching, granulating and peanut butter production are among the capabilities of this facility. Cold storage capacity totals 9 million pounds.

Peanut Processing Plant Project Report 2025: Setup Cost

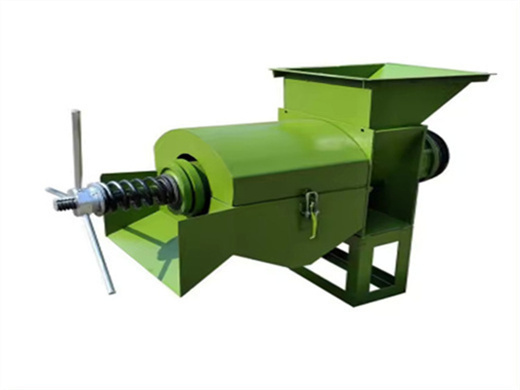

- Type: peanut oil processing machine

- Oil purity: pure

- Function: vegetable oil, sunflower oil, soybean oil filter

- Advantage1: Easy operation

- Price: factory price, lowest price

- Oil quality: high stage, food stage

IMARC Group’s “Peanut Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” report provides a comprehensive guide on how to successfully set up a peanut processing plant. The report offers clarifications on various aspects, such as unit operations, raw material requirements, utility supply

Bühler’s nut and seeds processing plants lead the market in customized solutions. From cleaning, roasting, blanching, optical sorting, grinding to chopping: Bühler offers complete lines for hazelnuts, peanuts, almonds and more.

Peanut Processing Plant Project Report: Setup & Cost

- Usage: peanut oil

- Production capacity: 5t/day-5t/hour

- Voltage: 0

- Core Components: Other

- Weight: 8 KG, 800 kg

- Dimension (L*W*H): 36*15.5*31cm

IMARC Group’s report, titled “Peanut Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a peanut processing plant. It covers a comprehensive market overview to micro-level information such as unit operations

Peanuts, a versatile legume, are widely cultivated for their nutritious seeds, which are a staple in many diets worldwide.

Peanut Processing Plant Manufacturer - Swastik Technology

- Type: cooking oil extraction machine

- Voltage: 220V/380V/440V

- Power (W): 5.5-22KW

- Certification: ISO9001

- Weight: 50tons

- Dimension (L*W*H): 48m*12M*15M(50tons )

A peanut processing plant serves as the basis of transforming raw peanuts into high-quality, ready-to-use peanut-based products. This modern setup integrates a wide range of machinery to simplify production. Whether it’s a peanut processing machine for shelling or a fully automated groundnut processing plant, each stage of operation is

Peanuts are nuts with a high oil content of 40% to 50%, making them a good material for oil press machines. The oil obtained from peanuts is very healthy and suitable for human consumption. Therefore, all countries have a great demand for peanut oil mill plants.We are a manufacturer and exporter of complete groundnut oil mill plants. We can supply completely custom business plans for peanut oil processing from small scale to large scale, from oil extraction, oil refining to oil filling.

peanut processing plant machine for in rwanda

- Raw Material: peanut

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 2850*1850*2560mm

- Voltage: 380V/50HZ/Three-phase

- Weight: 4850 kg

- Raw material: cotton seeds, sunflower, soybeans, peanuts, seeds, nuts, etc.

Vietnam Cashew Nut Processing Industry Shelling Machine. Peanut Shelling Machine; especially the rwanda. In 2015, Vietnam imported 853,000 tons of raw cashew worth $1.12 billion, up nearly 48% in volume and 73%

Peanuts occupy a large proportion of the edible oil market. The pressing process is a traditional and common peanut oil processing method, but it cannot fully extract the oil, leaving a relatively high residual oil in the cake. This has little impact on small and medium-sized oil mills, but for large edible oil processing plants, it is crucial to fully utilize oil resources to reduce production costs and increase profits, allowing the oil plant to stand firm in the fierce market competition.