peanut oil production machine and equipment in zimbabwe

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- Production capacity: 3.5-5.50 kg/h

- Voltage: 220/110 V

- Main components: Motor

- Weight: 9.5 KG

- Dimension (L*W*H): 430 * 230 * 350 mm

- Country: zimbabwe

In the production process of groundnut oil processing plant, oil refining processes are particularly important. Peanut oil refining equipment is a device that can process many impurities in crude oil. The presence of impurities in the crude oil not only affects the edible value and safe storage of oil, but also brings difficulties to deep processing. Using peanut oil refining equipment for oil refining, it will not remove all the impurities in crude oil, but rather removes the impurities contained therein that are harmful to food, storage, and human health. For example: protein, phospholipid, moisture, etc.

cold hot press peanut oil press machine price in zimbabwe

- Type: peanut oil processing machine

- Production capacity: 100%

- Voltage: 220 V/380 V

- Weight: 700kg

- Dimension (L*W*H): 1700*1100*1600mm

- Power (W): 7.5 kW

It can press more than 20 kinds of oil plant seeds, such as soybean, peanut, sesame, rapeseed, sunflower, olive, palm, coconut and flax seed, etc. 2. High oil yield and purer oil. The equipped vacuum filter is used to remove residue to ensure the pure oil quality and meet the standards of health quarantine.

So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Big Scale Peanut Oil Plant and Small Scale Peanut Oil Processing Plant. Below are the raw materials for peanut oil, as well as the workshop of KMEC’s peanut oil plant

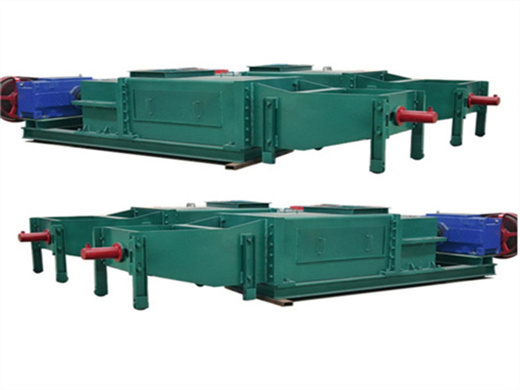

high quality peanut oil fractionation plant in zimbabwe

- Usage: peanut oil

- Press Series: Second

- Customized: Customized

- Material: Carbon steel Q235

- Weight: 160-1700 kg (Depends on the model)

- Production Press Automatic grade: Automatic and manual

Peanut oil is obtained from peanuts by different oil extraction methods. Peanut oil, also known as groundnut oil, is a kind of common vegetable oil. Generally, peanut oil comes in two different colors, one being light yellow ant the other is in deep yellow. Peanut oil contains highest mono saturated fat that is very easy to be absorbed by human body. Therefore, there are a large amount of consumers of peanut oil in the world.

The oilseed cleaning process in small oil mill plants is to improve the quality of oil and cake, increase the oil yield, increase the handling capacity, and protect the equipment. 3. Oilseed Roasting Machine. Rotary roaster equipment used in the edible oil plant is for heating the oilseeds which could increase the oil yield.

Automatic Integrated Oil Press Machine

- Type: cooking oil extraction machine

- Production capacity: 5t/day-5t/hour

- Dimension (L*W*H) : Customized

- Voltage: 220V/380V/400V/440V/450V

- Weight: 500 KG

- Main components: motor, pressure vessel, pump, PLC, gear

Designed for efficiency and convenience, it is ideal for small to medium-scale oil mill plants seeking high-quality oil with minimal labor and processing time. This versatile oil press machine can process a variety of oilseeds, including peanuts, sesame seeds, soybeans, rapeseeds, sunflower seeds, coconut meat, flaxseeds, mustard seeds, etc.

What parts are included in a peanut oil screw press? Peanut oil screw press mainly consists of five parts: hopper, gear box, press chamber, press screw and frame. Among them, the press screw is the key of the whole peanut oil screw press, and the choice of its material will affect the quality and service life of the press. 2024-08-26

OIL MILL PLANTS - 2 tons per day mustard oil mill plant

- Raw Material: peanut

- Automatic grade: Semi-automatic

- Voltage: 380v

- Production capacity: 150-250kg/h

- Power (W): 7.5kw

- Dimension (L*W*H): 1950*1300*1900

A mini oil mill is a set of machines used to extract oil from various oily seeds. These include peanuts, sesame seeds, sunflowers, cottonseeds, castor beans, and flaxseeds, to name a few.As the agricultural sector has become more technologically advanced, making it less accessible to more developed large-scale oil mills. , many individuals have chosen to set up full-fledged mini-mills at local

Peanut Frying Processing. This peanut frying line is mainly comprised of feeding machine, stone and impurity eliminator, feeder, automatic soaking machine of peanut, distributor, peanut peeler machine, selecting and conveying device, oscillating dryer, swing feed unit, airing device, storage device, quantitative feeder,peanut fryer, doffing machine, condiment machine, lifting and conveying