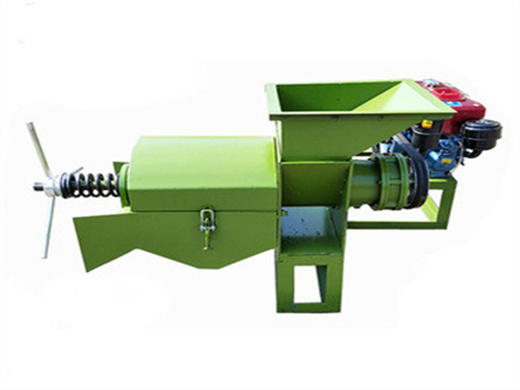

Electric Oil Press Oil Extraction Machine in bangladesh

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 300-3750kg/h, 7-9T/24H

- Voltage: 380V/220V

- Main components: motor, pressure vessel, motor

- Weight: 96800kg

- Dimension (L*W*H): 2000 *1100*1950mm

- Country: bangladesh

1200*480*1100mm. Get Quote. Edible oil is inseparable from people’s daily life. Edible oil requires an oil press for extraction. Therefore, investing in oil press machine can bring huge profits to investors. As a professional oil press manufacturer and supplier, our oil expeller covers almost all varieties on the market.

What are the common extraction methods of extracting peanut

- Type: peanut oil processing machine

- Production capacity: 1-100T/DAY

- Dimension (L*W*H): 8.8*6.4*9 ft

- Main components warranty: Others

- Warranty: One year warranty against manufacturer defect.

- Weight: 3700 KG

The peanut oil pressing method belongs to purely physical squeezing oil producing technology, the whole pressing process does not add any additives, which ensures that the extracted peanut oil can be ate directly.To make the peanuts reach the best pressing state, we usually need to use a series of pretreatment machines, like: cleaning machine

Beyond extraction, we’ll also talk about the machines you need to prepare your feedstock and refine the crude oil that you extract. Let’s dive right in. Peanut oil manufacturing: Raw material Peanut oil is made from peanuts, also called groundnuts (scientific name Arachis hypogaea). They are a preferred raw material to make edible oil

Mechanical Methods of Oil Extraction from Peanuts

- Usage: peanut oil

- Production capacity: 200TPD cooking oil refining machine

- Voltage: 220V/380V/440V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): depends on capacity

Consequently, the objective of this technique is to maximize oil extraction while generating defatted whole peanuts with high levels of protein and fiber and reduced oil content. The details are clearly explained in the patents LB-10,492 [ 48 ] and LB-10,493 [ 49 ] , in which MEPSI involved air-roasting peanuts as a pre-treatment.

In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting

Peanut Oil Processing Technology - ScienceDirect

- Type: cooking oil extraction machine

- Production capacity: 9-11 tons per day

- Dimension (L*W*H): 2850*1850* 3270mm (depends on capacity)

- Voltage: 220V/380V/440V

- Weight: 5000kg (depends on capacity)

- Main components: Motor

The leaching procedure mainly makes use of the solid-liquid extraction principle to select certain fat-dissolving organic solvents to extract the peanut oil. Generally speaking, the leaching solvent should meet the following conditions: good fat solubility, stable physiochemical properties, easy separation from the fat and meal, and be safe

New Type Peanut Oil Extraction Equipment in Mozambique. Read more. Personalized Peanut Oil Making Refining Equipment in bangladesh. Read more.

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Raw Material: peanut

- Production capacity: 120-500 kg/h

- Power: 2.2 kW

- Voltage: 220 V/380 V

- Dimension (length x width x height): 900*700*1200 (mm)

- Weight: 11000kg/160kg

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

The only difference is that the groundnut oil press production line need to be worked with groundnut oil solvent extraction plant. Groundnut oil pre-pressing machine can extract most of groundnut oil, the groundnut oil solvent extraction plant can recover almost all the oils and leaves behind only 0.7% to 1% residual oil in the raw material.