Degumming & Lecithin Processing: Soybean Oil Utilization

- Type: soybean oil plant

- Usage/Application: soybean

- Processed raw material: grass, rice husk, wood sawdust, biomass, straw, cotton stalks

- Pellet diameter (mm): 6 - 8

- Power (kW): 160kw

- Dimension (L*W*H): 1200x1320x850mm

- Product (kg/h): 1000 - 10000 kg/h<br /Voltage: 380v

- Country: johannesburg

Degumming of soybean oil is done for one of the following reasons: 1. To produce lecithin 2. To prepare degummed oil for long-term storage or transport 3. To prepare a degummed oil for caustic or physical refining The first reason is obvious and the second is necessary to prevent development of troublesome sludges in storage or transport.

Analysis on Soybean Oil Degumming Tec

- Type: soybean oil processing machine

- Production capacity: according to capacity

- Voltage: 110V, 220V, 380V , 440 V

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): according to capacity

Soybean oil degumming is one of the key steps in the soybean oil production process. Through hydration degumming technology, impurities and gums in soybean oil can be effectively removed and the quality of the oil can be improved. This article will deeply explore the principles, influencing factors, processes and equipment of hydration degumming.

What is Degumming Process in Oil Refining Plant? Degumming process in oil refining plant is to remove gum impurities in crude oil by physical or chemical methods, and it is an oil purification process. After screw pressing and solvent extracting from oilseeds, crude oil mainly contains triglycerides and few non-triglyceride.

Case study of chemical and enzymatic degumming processes in

- Usage: soybean oil

- Production capacity:1-500t/24h

- Voltage: customized

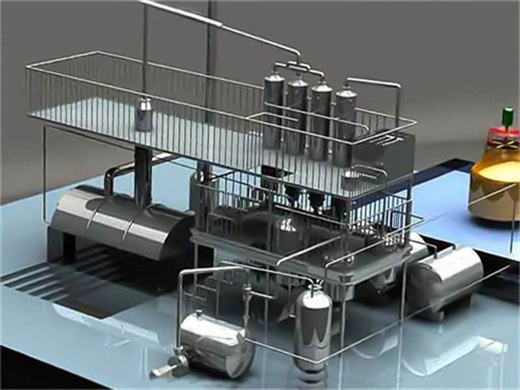

- Main components: motor, pressure vessel, pump, PLC, others, gears, bearings, motor, gearbox

- Weight: 500000 KG

- Dimension (L*W*H): According to your capacity

The vegetable oil degumming process plays a critical role in refining edible oil. Phospholipids (PL) removal from crude extracted soybean oil (SBO) by the enzymatic degumming process has been

With good-quality crude soybean oil, simple water degumming will reduce the phosphorus content to less than 50 ppm (0.005%), which is well below the 200 ppm (0.02%) level specified in the National Oilseed Processors Association (NOPA) trading rules for crude degummed soybean oil (15). The relation between phosphorus and phosphatide content is

THE PHYSICAL-CHEMICAL MECHANISM OF THE EDIBLE OILS DEEP - UB

- Type: cooking oil extraction machine

- Production capacity: 1-2000TPH

- Power (W) : 18.5KW

- Voltage: 220V/380V

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 1200kg

The removal of phospholipids (oil degumming) is the first stage of crude edible oil refining process. In the classic water/acid degumming process, the crude oil is treated with water, salt solutions (NaCl, CaCl2), or dilute acid (citric acid, phosphoric acid) to remove phospholipids. The phosphatides are changed into hydrated gums, insoluble in

Degumming is a process of removing these components from crude soybean oil to improve its physical stability and facilitate further refining at the soyabean oil plant. In this process, oil is treated with water to precipitate the hydratable phosphorous which is removed through the centrifugal separation system, and obtained gums are dried to

Degumming - an overview | ScienceDirect Topics

- Raw Material: soybean

- Production capacity: according to capacity

- Power (W): according to capacity

- Voltage: 220v, 380v, 440v

- Dimension (L*W*H): 430*230*350

- Weight: 1050 KG

Soybean oil extracted with the use of an expander has high phosphatide levels of 2.5–4.0%, and the ALCON process levels are 4.0–6.0% (Erickson, 1995d), but the phosphatides are more hydratable and more easily removed by water degumming. Normally, soybean oil from conventional solvent extraction has about 90% hydratable phosphatides and 10%

Capacity Range: Our refinery plants range from 2 to 5,000 tons per day (TPD), accommodating various production scales.; Custom Solutions: We provide tailored refining solutions based on the specific characteristics of different crude oils, such as palm oil, soybean oil, sunflower seed oil, peanut oil, rapeseed oil, corn germ oil, cottonseed oil, linseed oil, and rice bran oil.