palm oil press/palm kernel oil refinery process technology

- Type: palm kernel oil making machine

- Usage/Application: palm fruit, palm kernel

- Voltage: 220 V/380 V/440 V

- Power (W): according to different capacities

- Certification: CE ISO9001

- Weight: According to different capacities

- Dimension (L*W*H): 1200*400 *900mm3

- Country: johannesburg

Palm Oil Mill process is quite different from other vegetable oil seeds processing. Palm fruits consists a lot of fatty acid enzyme, which would hydrolyze palm oil. That’s the reason why palm fruit must be sent into processing in 24 hours.

BEST Oil Manufacturing Plant, Palm Oil Making Machines

- Type: palm oil refinery machine

- Voltage: 380V, 380v/50hz

- Power: customize, according to capacity

- Fields of Machinery Function: Cashew Processing Plant

- Weight: customize

- Dimension (L*W*H): customize

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

Palm kernel oil (PKO) extraction and refining techniques involves operations such as sorting of kernels, handling, mechanical pressing, filtration of crude oil, thermal, chemical and physical

Physical and Chemical Process in Palm Oil Refining Plant

- Usage: palm oil

- Voltage: 380 V

- Appearance: Uniaxial

- Customized: Customized

- Press Series: Second

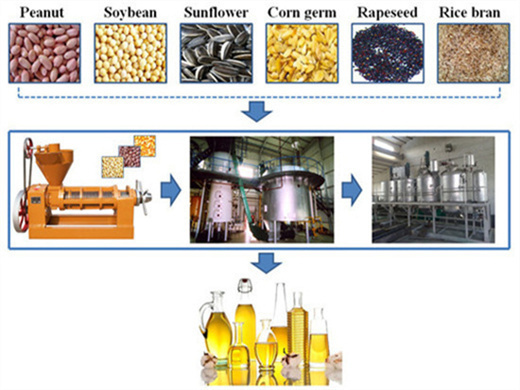

- Press Materials: Sunflower, Soybean, Coconut, Peanut, Mustard

The palm oil and palm kernel oil are steamed at a temperature of 240°C to 260°C to get away the odors and tastes, and then they are cooled into room temperature (about 55°C) for further use. This process have great impact on the quality of the final palm oil and palm kernel oil. Crude Oil Chemical Refining Plant

The quality of palm kernel oil obtained through above processing steps is high and enough to reach the standard of cooking oil. If there are special requirements, the palm kernel oil needs to be refined at professional Palm Kernel Oil Refining Plant. PKO Refinery - Edible Oil Refining Machine

Palm Oil Refining Machine

- Type: cooking oil refining machine

- Production capacity: 100% briquetting machine

- Power (W): 5.5 kw

- Voltage: 220 V/380 V/440 V

- Dimension (L*W*H): 2500*1600*2500

- Weight: 1300kg

Palm Oil Refinery is the main oil machinery and equipment to ensure the quality, grade and edible safety of oil in the palm oil processing process. The palm oil refining machine produced by Henan Hongde Cereals and Oils Machinery Co., Ltd. can flexibly adapt to different production needs with advanced technology and modular design:

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

Palm Oil Machine - Palm Oil Production Line

- Raw Material: palm

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 880*440*770mm

- Voltage: 220V/380V

- Weight: 160 KG

- Main components: Motor

The pulp part is processed by palm oil pressing machine to extract crude palm oil; the kernel part is crushed and extracted by a special palm kernel press. The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce

Palm oil refining technology refers to conversion of crude palm oil to refined oil involves removal of products of hydrolysis and oxidation, color and flavor. Adopts scientific designed palm oil refining machine process line including degumming, deacidification, decolorization, blenching, deodorization to obtain high quality refined palm oil.