Soybean Palm Oil Refining Plant in lagos

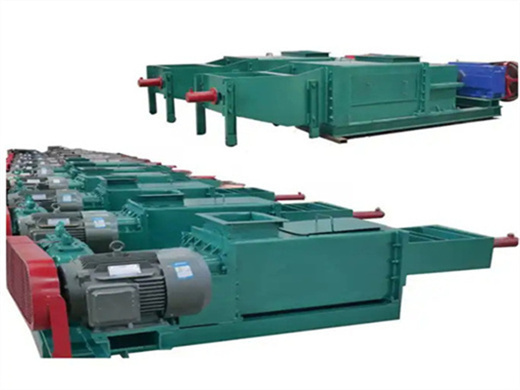

- Type: soybean oil equipment

- Usage/Application: soybean

- Production capacity: 300-8000 KG/H

- Voltage: 220v/380v/Customer request

- Main components: Motor

- Weight: 300KG

- Dimension (L*W*H): 1020* 720*798mm

- Country: lagos

In 2019/2020, lagos is among the top 10 importers of soybean oil, which represented more than 88.5% of its vegetable oil imports, followed by sunflower oil (11%) and rapeseed oil (0.5%). With an average annual growth rate of 3% per year, the total imports in vegetable oils have increased from 405,000 tons in 2007 to 616,000 tons in 2020, an

Soybean Oil Production Line

- Type: soybean oil refinery machine

- Production capacity: 10T~100TPD

- Voltage: 220V/380V

- Weight: related to capacity

- Dimension (L*W*H): 80*100*12m

- Power (W) : according to capacity

Soybeans are used as raw materials through pretreatment and leaching processes to obtain soybean crude oil and soybean meal, the soybean crude oil is put into the market after advanced physical refining and dewaxing process. Soybean oil occupies an important position in the world's vegetable oil production and consumption, mainly in cooking oil

3. 300TPD Soybean Oil Refining Production Line Introduction Based on the traditional oil refining technology, has developed the latest combined packing layer plate deodorization soft tower and the physical and chemical mixed refining technology for crude oil of any quality.

Refining Vegetable Oils: Chemical and Physical Refining - PMC

- Usage: soybean oil

- Voltage: 220V/380V/440V

- Power(W): 7.5kw

- Raw material: Vegetable seed

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

General overview of the chemical and physical refining process of crude oil. Physical refining of crude oils, therefore, overcomes the disadvantages of neutralization by sodium hydroxide . Indeed, this process, which is deemed to be eco-friendly, minimizes liquid effluents generation [29, 30].

This review presents recent technologies involved in vegetable oil refining as well as quality attributes of crude oils obtained by mechanical and solvent extraction.

Dingsheng Machine Introduces Comprehensive Soybean Oil

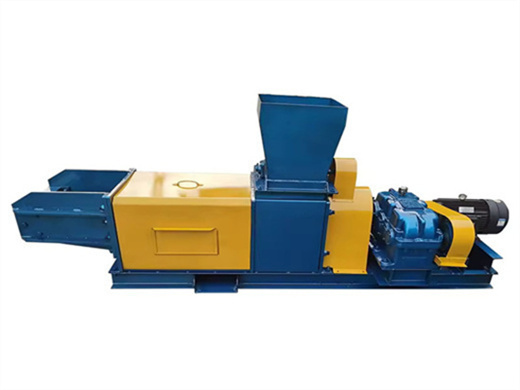

- Type: cooking oil refining machine

- Production capacity: 150-300kg/h

- Power: 5.5kw

- Voltage: 380V/50HZ

- Dimension (L*W) *H): 1200*550*1000

- Weight: 285kg

The soybean oil production process involves treating soybeans through either the pressing or solvent extraction method to obtain crude oil, which is then refined to produce high-quality edible soybean oil. The pressing method is a purely physical process that includes steps such as crushing, cooking, pressing, and filtering.

1. Superfine Fragrant Soybean Oil Refining Process. This workshop adopts the production technology of batch refining. According to the type and quality of the crude oil, the process parameters are adjusted and different refining methods are selected to produce the first and third-grade oils. The process equipment we provide has the following

Soybean Oil Refining Process Unveiled | Expert Guide

- Raw Material: soybean

- Production capacity: 1-100T/DAY

- Dimension (L*W*H): 80000*60000*14000mm

- Voltage: customized

- Weight: 80000 KG

- Main components: motor, pressure vessel, pump, PLC, motor, gearbox

The market for soybean oil production is driven by its usage in food processing and the growing trend of biofuels. Complete Soybean Oil Production Plant Layout. The refining of soybean oil, a process that removes impurities and enhances its stability, is a crucial step in ensuring the oil's superior quality. With its demand steadily increasing

If you want to know more information about soybean oil press, please feel free to contact us in the message form below. The soybean oil processing equipment manufacturer ABC Machinery can also customize the soybean oil processing plan according to the needs of customers, and is equipped with soybean oil processing equipment suitable for the manufacturer, so that the manufacturing process of the small soybean oil processing plant can proceed smoothly.