Groundnut Oil Plant in south africa

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 1-100T/D

- Voltage: 380V-440V

- Weight: different

- Dimension (L*W*H): according to capacity

- Power (W) : 1.5-3kw

- Country: south africa

How to make peanut oil from groundnuts? According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking Step 4: Pressing Step 5: Filtration After harvesting groundnut are received at processing facilities. Which country exports

Small Edible Oil Refinery Plant

- Type: peanut oil processing machine

- Production capacity: 1TPD-1000TPD

- Voltage: 0

- Key Selling Points: Energy Saving

- Weight: 3.5KG

- Dimension (L*W*H): 39*9*30mm

Process almost all kinds of crude oil for edible purpose: vegetable oil, palm oil, palm kernel oil, castor oil, sunflower oil, rice bran oil, soybean oil, sesame oil, cottonseed oil, canola/mustard oil, peanut/groundnut oil, etc. Machine Cost: $21,000~$115,000 (the exact price is based on capacity and other requirements of each equipment)

How does Alfa Laval refine crude oil into edible oil? Refining crude oil into edible oil requires deep process knowledge—from degumming, neutralization and dewaxing through to bleaching, deodorizing and GE and 3-MCPD mitigation. Edible oil producers worldwide rely on Alfa Laval know-how to remove impurities and volatile components and optimize refining processes. How do you refine crude oil

Peanut Oil Processing Plant Manufacturer - Oil Mill Plant

- Usage: peanut oil

- Certification: ISO, BV, CE, CE, ISO9001, BV, etc...

- Product type : Cooking oil refineries in Indonesia

- Residual oil in flour: ≤ 1%

- keyword: cooking oil productions

- Power: as needed

Then the cleaned peanut seeds are sent to the oil milling plant to be pressed into oil by oil presses. However, the crude peanut oil usually contains a number of impurities. So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing.

Sine establishment, we have help our customers built many oil production plant project around the world. There are at least 60 countries where we have built or exported cooking oil manufacturing machine including Zambia, south africaia, Ghana, lesotho, Cameroon, Mexico, Jamaica, Russia, Australia, Thailand, Moldavia, etc.

process and production of peanut oil - edible oil press

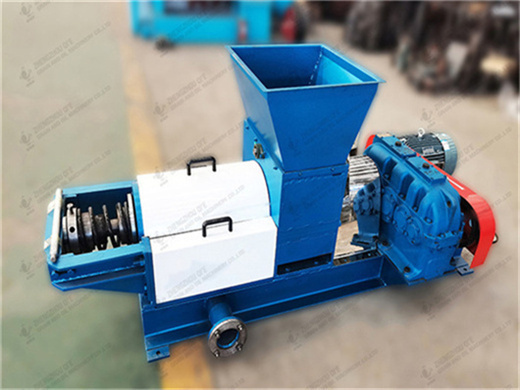

- Type: cooking oil extraction machine

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): According to capacity

- Main components: motor, pump, gear, bearing, motor, gearbox

- Guarantee : 1 year, 12 months

- Weight: 500 KG

9.10.2.2 Peanut Processing. stored, and processed for various uses (oil production, roasting, peanut butter production, etc.). Major process steps include processing peanuts for in-shell consumption and shelling peanuts for other uses.

We offer you complete peanut oil production solutions. No matter small peanut oil plants from 1 TPD to 50 TPD, or large-scale peanut oil plants up to 5,000 TPD, we will work with you to make the best solution. Our peanut oil production line is a comprehensive, multi-stage setup designed to extract and refine oil from peanuts.

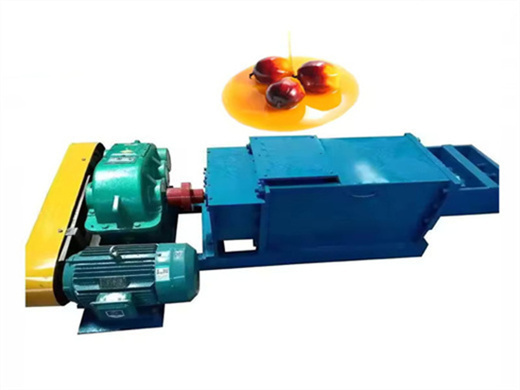

Peanut oil processing plant - cooking oil making machine

- Raw Material: peanut

- Production capacity: 5TPD

- Dimension (L*W*H): 1320*440*695mm

- Voltage: 220v

- Weight : 330 KG, 330 kg

- Main components: pressure vessel, pump, motor

2) Peanut oil solvent extraction workshop: After the pre-treatment, the next step is solvent extraction, which is using the solvent to exact oil from the peanut cakes. By this kind of technology, the residual oil ratio in the oil meal is less than 1%. Peanut oil solvent extraction plant and working process flow chart. 3) Peanut oil refinery plant:

We offer various high-quality oil press machines for peanuts, soybean, etc oil processing.we can also customize oil processing lines according to different oil crops. Read More Our technical teams are technically experienced in giving special attention to the project evaluation process.