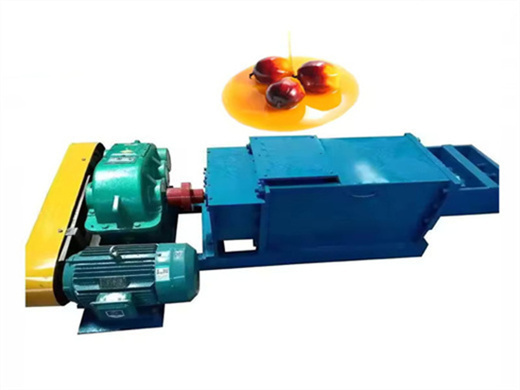

Oil Press Plant Hcrank Oil Press in mozambique

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 50%

- Voltage: 380/50 HZ

- Main components: motor, pressure vessel, Pump, PLC, Gear, Bearing, Motor, Gearbox

- Weight: 2000 kg

- Dimension (length x width x height): 2800*1600*2500

- Country: mozambique

Oil Press Machine. The large oil press machine is a continuous oil expeller which is suitable for preliminary pressing-solvent extracting press or twice pressing process in small and medium-sized oil plant, and used to handle with oil seeds such as rapeseed, peanut, sunflower, and cottonseed kernels. Production Capacity: 1-15tph. CONSULT.

Buy Cost Effective Palm Oil Production Equipment to Start

- Type: palm oil processing machine

- Production capacity: 1-1000 TPD

- Voltage: 220V/380V/415V

- Certification: ISO9001

- Dimension (L*W*H): 1200*400*900mm3

- Power (W): 1-30kw

Crush the flesh of the palm, destroy the nucleus, and prepare for the next press. Oil Pressing: Screw palm oil press is a common press equipment. After pressing, a mixture of oil and water can be obtained and pressed cake (fiber cake). Crude Palm Oil: A filter is used to separate the fibers in the wool oil. The oil and water are then separated

Besides palm oil screw press machine, Doing Machinery also supply 1tph, 5tph, 10tph, 15tph double screw palm oil press machine, 1-15tph small scale palm oil processing machine, 15-45tph medium scale palm oil processing machine and 45-120tph large scale palm oil processing machine and so on. Whatever your needs, we all can customize the most

30~60 TPD Complete Soybean Oil Extraction Plant Sent to mozambique

- Usage: palm oil

- Production capacity: 9-11 tons per day

- Voltage: 220V/380V/440V

- Item: cooking oil making machines

- Weight: 5000 kg (depends on capacity)

- Dimension (L*W*H): (depends on the capacity)

The final refinement yields pure soybean oil. The process of degumming: gross oil → hydration degumming → oil-water separation → vacuum drying → precision filtration → finished oil. The pressed gross soybean oil should be refined through a soybean oil refinery to obtain pure edible oil. (Related article: How to Refine Soybean Oil >>)

For mini palm oil mill plant with 1~10 ton per day production output, the processing flow is relatively simple, including threshing, digesting and sterilizing, oil pressing and oil filtering. One of the reasons why small scale palm oil mill are very common in the global market including Indonesia and south africaia is that they are affordable and they

Automatic palm oil milling machine - Palm oil extraction machine

- Type: cooking oil extraction machine

- Production capacity: 10 TONS /DAY

- Dimension (L*W*H): 2261MM*686MM*1423MM

- Voltage: 50 HP

- Weight: 1000 KG

- Main components warranty: 5 years

Free installation of palm oil processing plant. Palm oil extraction machine. The list of palm oil processing equipment. 1-2tph mini palm oil processing machine. 5tph small scale palm oil processing machine prototype. Palm fruit thresher machine. 1tph, 5tph, 10tph, 15tph double screw palm oil press machine

Hot Sale in the Market Automatic Peanut Spiral Screw Oil Press Oil Making Machine Soybean Oil Plant. Price Palm Palm Fruit Small Screw Oil Press Machine

Palm Oil Machine - Palm Oil Production Line

- Raw Material: palm

- Production capacity: 10-3000L

- Dimension (L*W*H): 1500*750*1800mm

- Voltage: 220V/380V

- Weight: 500 KG

- Main components: motor, pressure vessel, PLC, OTHERS

Main Station of Palm Oil Extraction Plant( Whether it is a small scale palm oil machine or large scale palm oil processing plant all include the following station): 1) Palm fruit reception station; 2) Palm fruit sterilizing station; 3) Palm fruit threshing station; 4) Palm fruit digesting & pressing station; 5) Crude palm oil clarification station;

Before making your business plan for starting a palm oil extraction factory, it is important to learn about the palm oil mill process. The process of palm oil extraction is very different from the processing of other seeds. Gnerally, palm oil mill includes 6 processes: fruits reciving, cooking/sterilizing, threshing, digesting, oil pressing, crude oil clarification, refining and fractionation, and pal kernel recovery.