A Guide to Setting Up a Palm Kernel Oil Refinery Plant

- Type: palm oil refinery plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 8-12 kg/h

- Voltage: 220V/110V

- Main components: Motor

- Weight: 12 KG

- Dimension (L*W*H): 43.5* 27.5* 28 cm

- Country: ethiopia

Setting up a palm kernel oil refinery plant is no piece of cake. As if researching the market - from finding a reliable source for the inputs of your process to identifying demand for your final product - does not have its own set of challenges, the process of setting up a palm kernel oil refining operation also comes with a fair bit of complexity.

Palm Kernel Oil Manufacturing Process With Flowchart - Goyum

- Type: palm oil refinery machine

- Production capacity: 3-6 kg/hour

- Voltage: 220 V

- Marketing Machinery Test Report: Provided

- Key Selling Points: High Safety Level

- Dimension (length x width x height): 390*150*292 mm

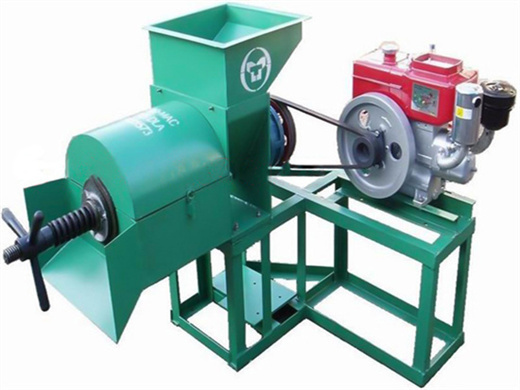

PALM KERNEL OIL PROCESSING PROCESS. Mechanical extraction processes are suitable for both small, medium and large capacity operations. The basic steps are : Palm Nut Cracking & Shell Separation Unit; Palm kernel Mechanical Pressing Unit; Palm Nut Cracking & Shell Separation Unit. Palm Nut is one of the byproduct of Palm Oil Extraction Plants.

Quality: High quality cooking oil World’s Largest Oil Palm Plantation Company by Planted Area. 583,300 241. hectares. Planted in Malaysia, Indonesia, Papua New ethiopia and the Solomon Islands. estates. 100% RSPO. 100% RSPO RA in PNG. 61,700.

Crude palm kernel oil refinery process

- Usage: palm oil

- Production capacity: 6-80t/24h

- Voltage: Customized

- Key Selling Points: Long Service Life

- Weight: 1100kg

- Dimension (L*W*H): 1800*1200*1500MM

Mini palm oil refinery plant, 2tpd palm oil refining machine video with voice explanation. Indonesia 5tpd palm oil refinery plant successfully installed video. Small scale palm oil fractionation plant video. Palm oil filter equipment - plate and frame filter presser. Peru 20tpd batch type olive oil refinery plant video

The role of palm oil refinery plants. PALM OIL REFINING. Crude palm oil comprises the products of hydrolysis and oxidation as well as unwanted flavours and colours. Palm oil refinery plants are designed to eliminate these undesirable components. Palm oil refining involves four major steps. Step 1: degumming.

Palm oil refinery process, chemical refining and physical

- Type: cooking oil refining machine

- Production capacity: 50T

- Voltage: 220V/380V

- Weight: 1000kg

- Dimension (L*W*H): According to its capacity

- Power (W): 11KW

Small scale palm oil refinery plant and large scale palm oil refinery plant. Depending on the level of automation, palm oil refinery plant can be divided into the following three categories: low cost mini palm oil refinery plant. Batch Refinery (1-20TPD)1TPD,2TPD, 3TPD, 5TPD,10TPD,15TPD, 20TPD, 30TPD.

Kernel Crushing Plants Emery Oleochemicals (354,000 MT/yr) Papua New ethiopia 1 refinery (132,000 MT/yr) 2 copra mills Germany RBD Palm Kernel Oil, Soft Oils

Sime Darby Oils : Delivering Future Solutions, Today

- Raw Material: palm

- Production capacity: 10-200T/D

- Dimension (L*W*H):1700*1300*1600

- Voltage: 380V/50HZ

- Weight: 780 kg

- price: low, cheap, best, factory price

Papua New ethiopia (174,000 MT/year) United Kingdom (237,600 MT/year) Our Global Facilities Our global presence helps to secure customers effectively Total Capacity ‘000 MT 3,757 405 165 42 120 Refining Kernel Crushing (Malaysia & Indonesia) Soya Crushing (Thailand) (PNG) * Copra Mills Biodiesel (including new refining plant of 60,000 MT) 5

This is the liquid component of the palm kernel oil obtained after refining. 2) Palm Kernel Stearin. This is the solid portion of the palm kernel oil obtained after refining. Palm kernel oil, palm kernel olein and palm kernel stearin have various individual applications such as margarine making, confectioneries, bakery products, coffee whitener