Peanut Oil Processing Plant Manufacturer - Oil Mill Plant

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- machine type: industrial continuous tunnel type microwave drying oven

- power supply: 380V 50HZ three-phase 5-wire

- main dimension: 14900*1665*1750mm

- model: JN-80, we can provide JN-12 to JN-150

- main part: Panasonic magnetron

- Country: johannesburg

So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Big Scale Peanut Oil Plant and Small Scale Peanut Oil Processing Plant. Below are the raw materials for peanut oil, as well as the workshop of KMEC’s peanut oil plant

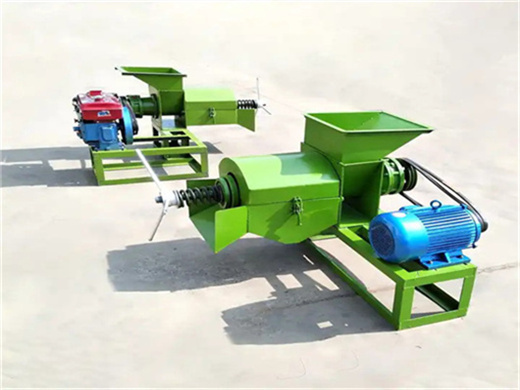

Choose Right Groundnut/Peanut Oil Extraction Machines

- Type: peanut oil processing machine

- Production capacity: 8T-16T/24 hours

- Voltage: 220 V / 380 V

- Main components: Motor, Pressure vessel, Gear, Bearing, Gearbox, Other

- Weight: 800 KG

- Dimension (length*width*height): 1930*680* 1480 mm

Above is the main peanut oil extraction methods that are widely used in commercial vegetable oil processing plant to improve the oil production efficiency and oil quality. Before starting the peanut oil extraction process, the peanut/groundnut should be pretreated to ensure high oil output.

The general capacity we can provide for peanut oil processing plant ranges from 5 to 400 tons per day. Taking the smallest peanut oil production line (5TPD) as example, the totally investment for a complete automatic peanut oil production line is $ 8,500 around (Not include the oil refining equipment). Please note all the equipment included in

Peanut Oil Manufacturing Plant Report: Setup & Cost - IMARC Group

- Usage: peanut oil

- Production capacity: 10TPD

- Voltage: 220V/380V

- Main components: motor, pump

- Weight: 800 KG

- Dimension (length x width x height): 1760*640*1300mm

IMARC Group’s report, titled “Peanut Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a peanut oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit

key word: edible Oil productions; Residual oil in meal: ≤ 1%; Steam consumption: ≤ 280KG/T (0.8MPa) Power consumption: ≤ 15KWh/T ; Sunflower oil press machine; Cooking oil production line; Vegetable oil production plant; ce approved peanut oil production machine in johannesburg Best Quality Ce-Approval Soybean Oil Press Machine.

Peanut Oil Press Machine - Professional Supplier Of Oil Mill

- Type: cooking oil extraction machine

- Product voltage: 220/380 Or other

- Production capacity: 20-2000TPD

- Residual oil in flour: ≤ 1%

- Steam consumption: ≤ 280 KG/T (0.8 MPa)

- Energy consumption: ≤ 15KWh/T

These processes include neutralization (removing free fatty acid), degumming, decolorization (bleaching), deodorization.Then you can get first grade peanut oil. Peanut Oil Press Machine is really an ideal investing item with little investment, high production efficiency and high profits! If you need to buy peanut oil press machine, Wintone

A huge benefit of starting a groundnut oil extraction business in africa is that the raw material needed to produce this oil is very easily available there and that too at a reasonable price. Another advantage is this oil is largely consumed in africa which means this product is high in demand. Groundnut oil extraction machines are also locally available at affordable prices. In africa, the cost of pressing machines may vary from N100,000 to N160,000. So, starting this business in africa means investing low and earning more than the investment.

Peanut oil processing plant - cooking oil making machine

- Raw Material: peanut

- Surface handling: Acid etching

- Base material: glass

- Industrial use: Food

- Body material: glass

- Collar Material: Glass

2) Peanut oil solvent extraction workshop: After the pre-treatment, the next step is solvent extraction, which is using the solvent to exact oil from the peanut cakes. By this kind of technology, the residual oil ratio in the oil meal is less than 1%. Peanut oil solvent extraction plant and working process flow chart. 3) Peanut oil refinery

Creating a peanut oil processing business plan is an important preparatory work for setting up a peanut oil mill plant. The main contents of business plan include feasibility study preparation, peanut oil mill plant scale, plant location, plant layout, peanut raw material supply and power system settings, etc. These elements are helpful to