Palm Oil Refinery Plant, Manufacturing Vegetable Oil Products

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1TPD-1000TPD

- Voltage: 220V/380V/440V

- Weight: 30 tons

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- liPower (W): 18.5 KW/T

- Country: johannesburg

Deodorization of Palm Oil. Palm oil deodorization is mainly a physical refining process belongs to steam deodorization. High pressure steam is introduced as a kind of stripping agent to remove various volatile components. The deodorization of palm oil usually processed at high temperature (>200°C) and low pressure. Palm Oil Deodorization

Edible Oil Deodorization Plant Manufacturer - Kumar Metal

- Type: palm oil processing machine

- Production capacity: 1t/day-1t/hour-100%

- Voltage: 380V/50HZ

- Main components: engine, motor

- Weight: 300 KG

- Dimension (L*W*H): 2600* 1300*2300mm

Kumar’s EcoPack Deodorizer is used to physically refine oils (palm, palm kernel, rice bran, etc) with an FFA content above 3%. Oil is fed to a column with specially designed structured packing. The oil flows down in a thin line along the packing while the counter flowing stripping steam efficiently strips off the FFA.

The company is very successful in the palm oil processing industry. To cement this position, the company ordered the first SoftColumn deodorization plant in Indonesia, accompanied by dry fractionation plants. This Alfa Laval SoftColumn deodorization installation provides the company with a processing capacity of 1,000 tonnes of palm oil daily.

DEODORIZATION SECTION - Palm Oil Factory

- Usage: palm oil

- Voltage: 380V/50HZ

- Power (W): according to capacity

- Color:Yellow

- Certification:ISO BV CE

- Dimension (L*W*H): 1200*400*900mm3

Palm Oil Refining Deodorization Section Introduction: The qualified decolorized palm oil enters into the spiral plate heat exchanger to recover most of the heat, and next goes to high pressure steam heat exchanger to be heated to the process temperature of 240-260 degrees Celsius, and then enters the deodorizer tower.

The palm oil extraction is to be done with the fresh palm fruit to avoid the deterioration of palm oil so the countries doing the cultivation are extracting the oil themselves. The crude palm oil comes out as yellow red or dark yellow in colour and the taste of the crude palm oil is sweat.

Deodorization - K-TEK

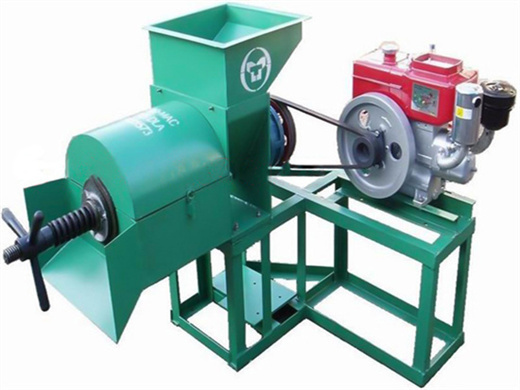

- Type: cooking oil extraction machine

- Production capacity: 98%-100%

- Power (W): 5 .5 KW ~ 15 KW

- Voltage: 380

- Dimension (L*W*H): 2200*1600*2150

- Weight: 780 kg

Deodorization is the quality-defining process step in refining oils and fats and therefore particularly significant. Undesired by-products remain in the oil or fat following the preceding refining processes. These can impair the odor, taste or shelf life of the product and must therefore be removed. Some of these by-products are still bound in

Oil from the deodorizer is cooled and stored after passing through the heat exchanger. The free fatty acids are collected and stored as by-products. Oil Deodorization Flow Chart . Palm Oil Refining Process. Palm oil is one of the most widely consumed edible oils in the world today. Palm oil is obtained from the flesh of the palm fruit.

Palm oil refining deodorization section - Palm oil extraction

- Raw Material: palm

- Production capacity: 50-600 kg/h

- Dimension (L*W*H): 140*86*126 mm

- Voltage: 220/380 v

- Weight: 280 KG

- Main components: motor, pump, gearbox

The qualified decolorized palm oil enters into the spiral plate heat exchanger to recover most of the heat, and next goes to high pressure steam heat exchanger to be heated to the process temperature of 240-260 degrees Celsius, and then enters the deodorizer tower.

Vegetable oil is heated to the desired temperature in a multi-compartment Vacuum Heater with counter current flow of vegetable oil and heating medium i.e. High Pressure Steam or Thermic Fluid. Pre-heating is gradual and methodical so that all of the oil comes in contact with this sparging system at the free surface exposed to vacuum.