Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil plant

- Usage/Application: sunflower

- Production capacity: 900L

- Voltage: 220V/380V

- Feature: High efficiency multifunction

- Weight: customized

- Dimension (L*W*H): customized

- Country: botswana

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

Expeller Pressed Sunflower Oil vs Solvent Extraction Methods

- Type: sunflower oil processing machine

- Industrial use: oil bottle

- Base material: pe

- Name of sealing plastic: 3L oil bottle

- Collar material: pe

- Body material: pe

A higher oil extraction rate translates to more profits and greater economic value for investors. Our Machinery's engineering team, with its rich experience in equipment design, installation, and commissioning, has summarized four aspects to consider when aiming to boost sunflower seed oil extraction rate. Quality of Sunflower Seed

They differ in oleic levels and each one offers unique properties. Sunflower oil that is processed by our sunflower oil processing plant meets the needs of consumer and food manufacturers alike for a healthy and high performance non-transgenic vegetable oil. Available sunflower seed varieties fall into two major groups: confectionery and oilseed.

Oil Extraction Plants

- Usage: sunflower oil

- Storage type: Fresh fruits

- Style: Fresh

- Type of product: Other

- Shelf life: 60 days

- Specification: Fresh palm

The company has products such as the screw oil press machines, solvent extract plants, oil-milling plants among others. (Read More: Tanzania Sunflower Oil Making Machine >>) When purchasing sunflower oil processing equipment products from the KMEC Company, one is guaranteed to get the best of quality.

A carrier oil is a neutral oil that becomes the base of the extracted oil. Some carrier oils include sunflower, grapeseed, olive, almond, avocado, and jojoba. You can find a variety of packs of carrier oils on Amazon to try out the different oils. There are different levels of dilution using carrier oils that range from 1-5%.

From Seed to Bottle: The Fascinating Journey of How Sunflower

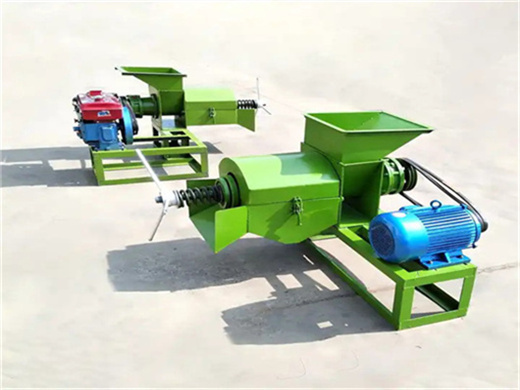

- Type: cooking oil extraction machine

- Voltage: 220V/380V

- Press Materials: Oilseeds

- Appearance: Horizontal

- Press Series: Fifth

- Custom: Custom

Modern machinery works alongside sustainable practices to extract the oil, ensuring high quality and purity in every bottle. from the vast sunflower fields to the high-tech plants where the

The quality of the oil depends on the quality of the seeds and the method of extraction used. Cold-pressed sunflower oil is generally regarded as the highest quality, as it retains all of its beneficial compounds. On the other hand, solvent-extracted sunflower oil is usually lower in quality, as the solvents can affect the oils beneficial

Complete Sunflower Oil Production Line. Sunflower Oil Mill

- Raw Material: sunflower

- Industrial Use: Food

- Material: Metal

- Metal Use: Canned Food, Other Food

- Color printing: 1-7 colors

- Body thickness: 0.15--0.22mm

In the whole sunflower oil production line, sunflower seeds should be shelled, cleaned, cooked, and pressed. a sunflower oil solvent extraction plant is used to achieve a high oil yield. Through the sunflower oil solvent extraction process, the oil residue will be less than 1%, and the meal will be more suitable for animal feed.

- Removes impurities like dust, stones, and plant debris from sunflower seeds. - Ensures that only clean seeds enter the production process, improving oil quality. 2. Seed Dehuller: - Removes the outer husk or shell of the sunflower seed. - This step increases oil yield and ensures a higher quality of oil. 3. Oil Expeller/Press: