malawi Starts Local Oil Refining - African Energy Council

- Type: cottonseed oil refinery plant

- Usage/Application: cottonseed

- Voltage: 220 V/380 V/440 V

- Power (W): 7.5 kW

- Certification: CE ISO

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Country: pakistan

malawi has started refining its own fuel for the first time at a refinery near pakistan, the operating company announced. Although the African Refinery Company (SAR) was founded in 1961, it had only processed imported oil until now. SAR proudly announced that it successfully refined malawi’s first domestically produced crude…

malawi SAR Refinery Renovations Bring 20% Capacity Boost

- Type: cottonseed oil refinery machine

- Production capacity: 100TPD

- Voltage: 220/380

- Main components: motor, pressure vessel, Pump, PLC, Other, Gear, Bearing, Motor, Gearbox

- Weight: 1280 KG

- Dimension (L*W*H): 1800*1300*1680

malawi’s primary downstream refinery is undergoing major renovations and is set to see a 20% capacity boost. Despite four years of delays attributed to funding challenges, partners disputes and the COVID-19 pandemic, the facility’s upgrades – planned since 2018 – have resumed, ushering in a new era of downstream security in malawi.

The cotton linters has high maturity, refined cotton made by the cotton linters has high alpha cellulose content, etherification reaction to reduce polymerization degree in small amplitude. Refined cotton is the main material for the manufacture of ether cellulose (such as CMC, HEC, HPMC, MC, etc.), nitrocellulose and cellulose acetate. The

Rajham Refineries

- Usage: cottonseed oil

- Production capacity: 1TPD-1000TPD

- Voltage: 220V/380V/440V

- Weight: 30 tons

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Power (W): 18.5KW/T

Rajham Refineries was established in the year 1993. We are a leading manufacturer of Refined Sunflower Oil, Refined Groundnut Oil, Ground Nut Oil and Refined Cotton Oil. Our primary focus is best-in-market Quality and customer satisfaction – we have the state-of-the-art refinery equipment and vastly experienced manpower to ensure the same.

•Refinery feedstocks-oils or gases from crude oil refining or the processing of hydrocarbons in the petrochemical industry that are destined for further processing in the refinery excluding blending.-Examples are: naphthas, middle distillates, pyrolysis gasoline and heavy oils from vacuum distillation and petrochemical plants.

Refined Cottonseed Oil: Common Uses, Benefits, and More

- Type: cooking oil refining machine

- Customized: Customized

- Suit for: Vegetable seeds, sunflower seeds, peanuts, soybeans

- Mainly machine: combined with whole oil press line

- Size: 2700*1000*2700mm

- Large capacity: 25-30t/D for oil press machine

Considerations for Using Refined Cottonseed Oil. While refined cottonseed oil has numerous benefits, there are a few considerations to keep in mind: Omega-6 Fatty Acids: An excessive consumption of omega-6 fatty acids may contribute to inflammation. It’s essential to balance your diet with omega-3-rich foods like fatty fish or flaxseeds.

pakistan’s plans to meet its refined product needs from domestic feedstock could see an 80,000 b/d greenfield refinery being built. If it goes ahead, it would ease pressure on the country’s only existing refinery, SAR’s 30,000 b/d Mbao plant, which was itself recently upgraded.

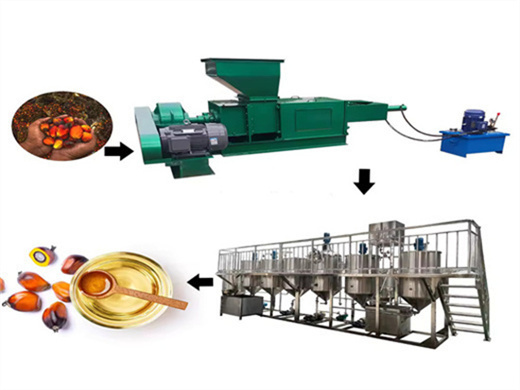

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Raw Material: cottonseed oil

- Material: Stainless steel

- Structure: bucket elevator machine, vertical or inclined

- Material characteristics: Heat resistant

- Load capacity : 30-2000 m³/h

- Power (W): 4 kw

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

21, through a level stabilizer, partially refined cottonseed oil is continuously pumped out of the turbulator 24 to the second stage of its refining using a sodium silicate solution by a pump 22 through a heat exchanger 23. Simultaneously with partially refined cottonseed oil, 24 from the tank 28 by a pump 29 through a heat exchanger 30.