Soybean Oil Refining Process Unveiled | Expert Guide

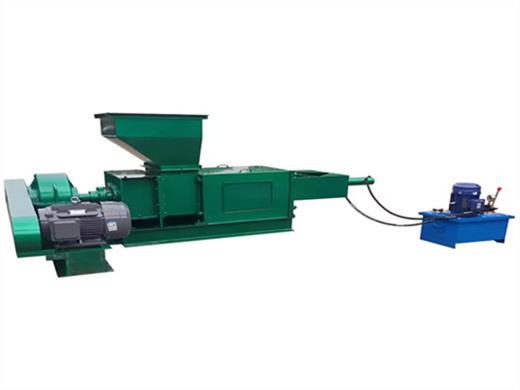

- Type: soybean oil plant

- Usage/Application: soybean

- Production capacity: 10T-3000T/D

- Voltage:380V,440V

- Weight:depends on capacity

- Dimension (L*W*H) :depends on capacity

- Power ( W): according to capacity

- Country: pakistan

Complete Soybean Oil Production Plant Layout. The refining of soybean oil, a process that removes impurities and enhances its stability, is a crucial step in ensuring the oil's superior quality. With its demand steadily increasing across industries, the market for soybean oil and its refined products is poised for further growth.

Soybean Oil Production Plant Overview - Oil mill

- Type: soybean oil refinery machine

- Voltage: 220V/380V/440V

- Power (W): 18.5KW/T

- Certification: ISO9001

- Weight: 30 tons

- Dimension (L*W*H): 48m*12M*15M( 30TPD)

The pretreated soybean flakes are sent to the soybean solvent extraction plant. The soybean oil extraction plant uses a kind of solvent (normal hexane) to absorb the oil from the soybean, and then the machines separate the solvent from soybean crude oil. The solvent can be recycled, and the soybean crude oil is refined by an oil refinery plant.

After removing the hexane, the extracted flakes only contain about 1% of soybean oil and is used as livestock meal or to produce food products such as soy protein. The hexane is separated from the soybean oil in evaporators. The evaporated hexane is recovered and returned to the extraction process. The hexane free crude soybean oil is then

Soybean Oil Extraction Plant | Soybean Oil Plant - Mectech

- Usage: soybean oil

- Production capacity: 150-2500 KG/h

- Voltage: 380 V

- Key selling points: Automatic

- Weight: 7800 KG

- Dimension (L*W*H): 2500*800*2300 mm

Crude SOYBEAN oil is obtained from SOYBEAN seeds which go through the preparatory steps before undergoing the solvent extraction process in soya oil refinery plant. The crude SOYBEAN oil is further refined for making it free from fatty acids, color pigments, and numerous other components harmful to human beings.

Soybean Oil Application. 1. In Food Industry. Liquid soybean oil is sold as “vegetable oil” or as a component of processed food like margarine, shortening, mayonnaise and various flavoring oils. The refined soybean oil is pale yellow, clear, transparent, odorless, and has a good taste. It can be used for cooking without foam and smoke.

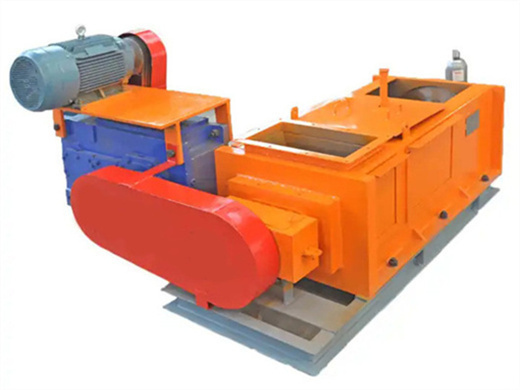

Soyabean Oil Refinery Plant

- Type: cooking oil refining machine

- OEM: Yes

- Raw material: Stainless steel

- Quality: High

- Oil rate:97%

- Capacity: 500-2500 kg/day

Soyabean Oil Refinery by Tinytech comes in various capacities ranging from entry level small scale plant of 5-TPD to medium and big scale plants upto 30-TPD. We are leading manufacturers and exporters of Soyabean Oil Refinery Plant systems for processing the crude soya oil into the refined soya oil.

Generally, Pressure Leaf filters are used for this filtration. These are removed from the filter as cake and the degummed, alkali refined, and bleached soybean oil is taken to the deodorization process. This 'work-in-process' (WIP) soybean oil is then deodorized using sparging steam in a deodorizer.

SOYBEAN OIL QUALITY FACT SHEET - REFINING - U.S. Soy Delivers

- Raw Material: soybean

- Production capacity: 10T-3000TPD

- Power (W): depends on capacity

- Voltage:220V/380V

- Dimension (L*W*H): depends on capacity

- Weight: depends on capacity

Soybean Oil Refining Stages Crude degummed soybean oil (CDSBO) must be refined to produce high-quality soybean oil that is suitable for human use and many industrial uses. The traditional method to refine CDSBO is called caustic refining. This method uses a chemical process to refine CDSBO and produce refined, bleached and deodorized soybean

Soybean oil is a major vegetable oil that is used in a variety of food products, as well as in industrial applications. The soybean oil refinery process is used to remove impurities from crude soybean oil, making it safe for human consumption and suitable for industrial use. The soybean oil refinery process typically consists of the following